| Tweet |

Custom Search

|

|

|

||

TM 9-8000

gage whose operation is the same as the gage used with

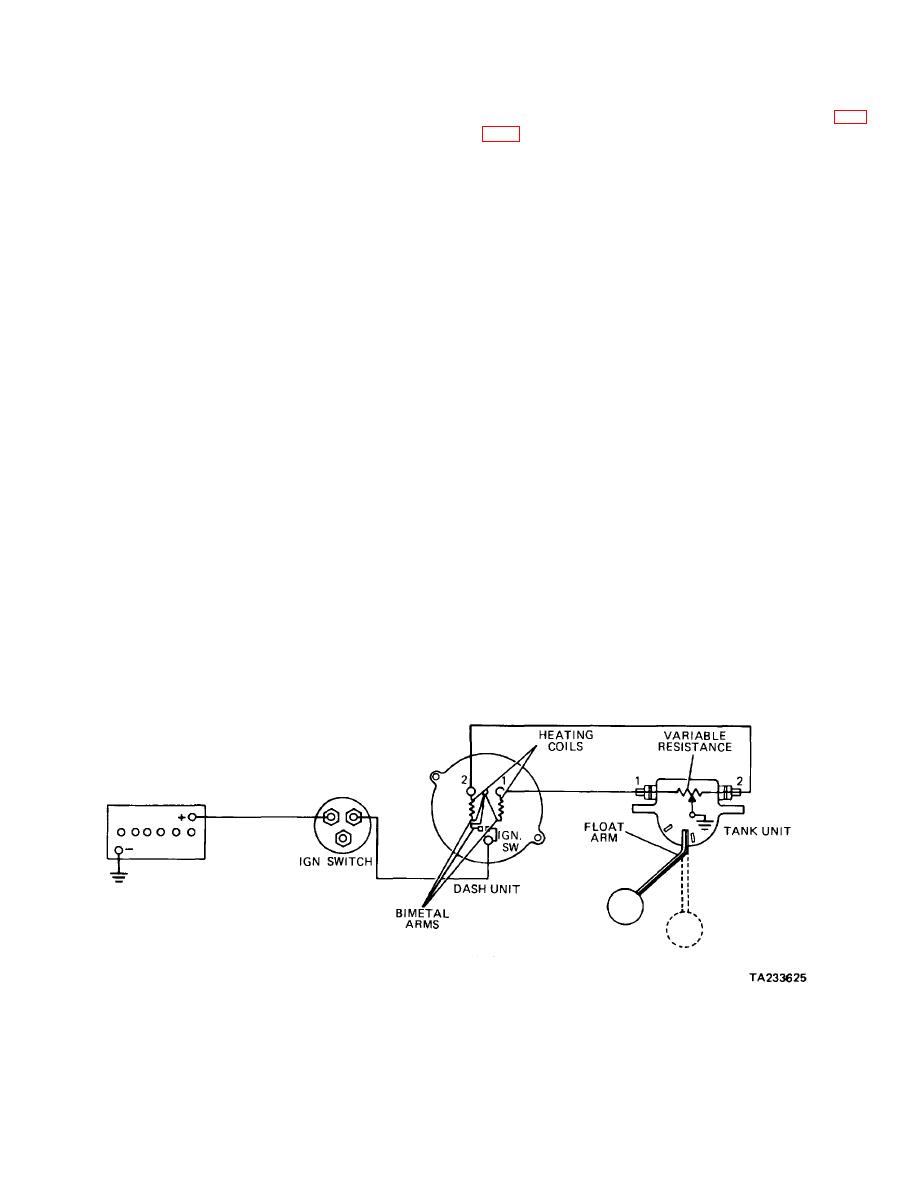

c. Thermostatic Fuel Gage: Differential Type (Fig.

the self-regulating system described ir paragraph 17-3a.

The differences in the system are the use of a variable

instrument panel gage whose operating principles are

resistance fuel tank sending unit and an external voltage-

much the same as the thermostatic gage described In

limiting device. The sending unit controls the gage

paragraph 17-3a. The differential-type thermostatic gage,

through the use of a rheostat. A rheostat is a wire wound

however, uses two electrically heated bimetallic strips

resistance unit whose value varies with it' effective

that share equally in operating and support- ing the gage

length. The effective length of the rheostat is controlled

pointer. The pointer position is obtained by dividing the

in the sending unit by sliding brush that is operated by

available voltage between the two strips (differential).

the float arm. The power supply to the gage is kept

The tank unit is a rheostat type whose operating

constant through the use of a voltage limiter. The voltage

principles are much the same as the tank unit described

limiter consists of a set of contact points that arc

in paragraph 17-3b. The tank unit in this system,

controlled by an electrically heated bimetallic arm.

however, contains a wire-wound resistor that is

connected between two external terminals. Each one of

(1) When the fuel tank is empty, the float lays on

the external terminals connects to one of the instrument

the bottom. The float arm will position the contact brush

panel gage bimetallic strips. The float arm moves a

so that the full length of the rheostat resistor will be

grounded brush that raises resistance progressively to

utilized. The resulting high resistance will drop voltage to

one terminal, while lowering the resistance to the other.

the gage sufficiently so that the pointer will rise only to

This causes the voltage division and resulting heat

empty.

differential to the gage strips that formulate the gage

readings. Two additional bimetallic strips are provid- ed

(2) As the fuel level rises in the tank, the float

for temperature compensation. In addition, one of these

will raise the float arm, which, in turn, will move the

blades operates contact points to limit voltage to

contact brush on the rheostat resistor. As the float arm

approximately 5 volts.

moves upward, the resistance will decrease

proportionally, resulting in a proportional voltage increase

(1) When the tank is half full, the float arm

to the gage. The gage readings will increase

positions the contact brush midway of the rheostat. This

proportionally, resulting in accurate readings of the fuel

causes equal resistance values to each sending unit

level in the tank.

circuit, resulting in equal heating of the gage bimetallic

strips, causing the gage to read one-half.

(3) The voltage limiter effectively will en- sure a

constant supply of current regulated to the equivalent of

(2) Fuel levels above or below half will cause

5 volts, to provide accurate gage readings regardless of

the tank unit to divide the voltage to the gage bimetallic

electrical

system

voltage

variations.

strips

in

the

correct

to

Figure 17-8. Thermostatic Fuel Gage: Differential Type

17-6

|

||

|

||