| Tweet |

Custom Search

|

|

|

||

TM 9-8000

ted suitable high-temperature and humidity resistance in

practical for the identification of circuits in future military

these applications.

Tape 19207-10886484 has

vehicle electrical systems. There are several practical

demonstrated adhesive qualities that withstand steam

methods used to apply wire identification characters on

cleaning and the oily, high-temperature environment

wiring assemblies. Four of the commonly employed

associated with vehicle power packs.

methods are:

a. Lettering may be hot stamped per MIL-M-81531,

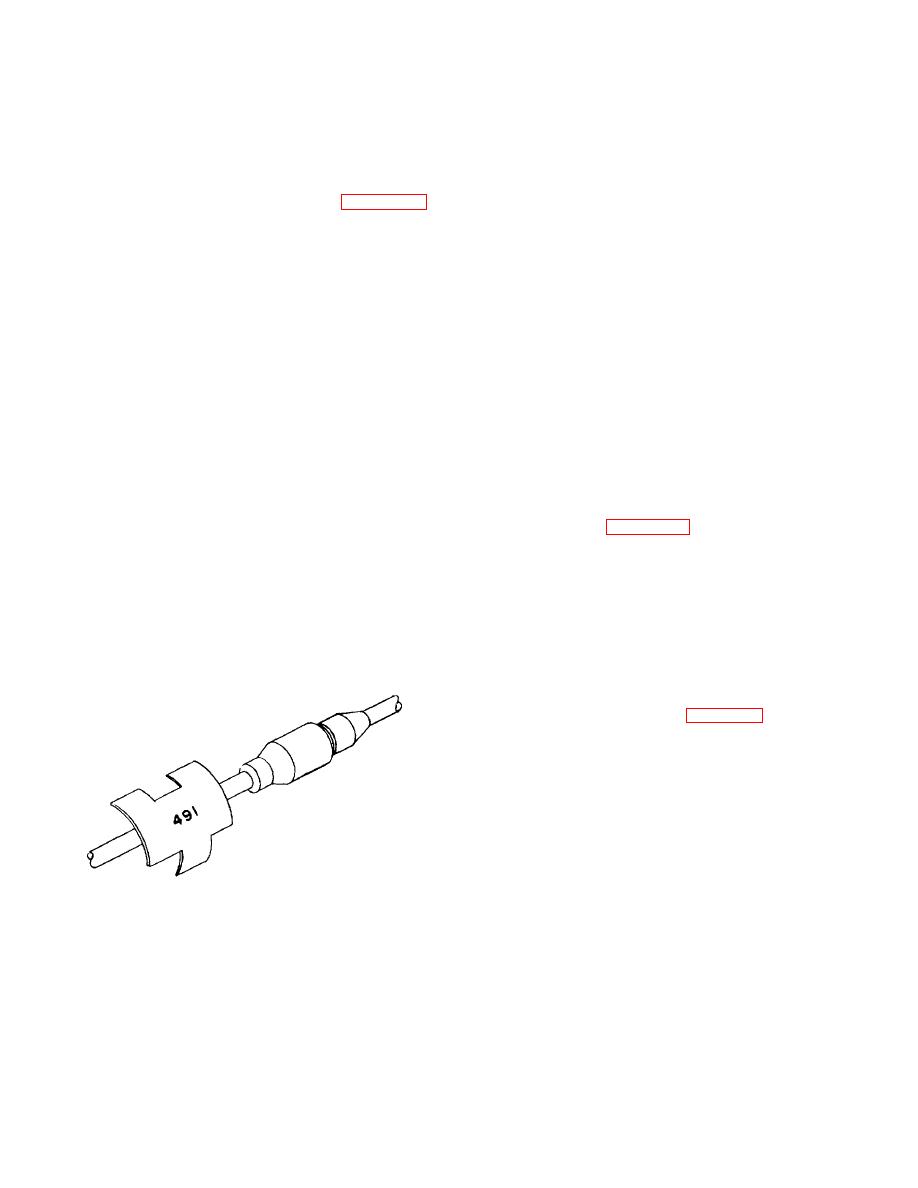

17-23. Wiring Harness Identification (Fig. 17-35).

with 0.05-in. minimum height type, directly on the wire or

Wires in an electrical system should be identified by a

cable insulation using white letters on dark backgrounds

number, color, or code to facilitate tracing circuits during

or black letters on light backgrounds.

assembly, troubleshooting, or rewiring operations. This

identification should appear on wiring schematics and

b. Lettering may be hot stamped per MIL-M-81531,

diagrams and whenever practical on the individual wire.

with 0.05-in. minimum height type, on MIL-1-23053/2

The assigned identification for a continuous electrical

heat-shrinkable sleeving, length and diameter as

connection should be retained on a schematic diagram

required, assembled over the wire insulation.

until the circuit characteristic is altered by a switching

point or active component. An extension of this system

c. Lettering may be indented or embossed with

involves the use of suffix letters on wiring diagrams and

0.093-in. minimum height type on band, marker blank,

wiring assemblies to identify the segments of wires

MS39020, style and length as required, in accordance

between terminals and connector contacts. The use of

with MIL-STD-130. Of these, the metal marker bands

suffix letters is advantageous when it is necessary to

with indented or embossed characters are the most

identify several individual wires of a common circuit that

durable and they remain legible even if painted over.

are bound in the same harness.

Tank-automotive electrical circuits have been identified

17-24. Wire Terminal Ends.

over the years with unique numbers for specific circuits,

based on the premise that maintenance personnel would

a. General (Fig. 17-36). Wire lug terminals are

become familiar with wire numbers for these circuits and

divided into two major classes: the solder type; and the

this familiarity would facilitate their ability to service a

solderless type, which also are called the pressure or

variety of vehicles. Furthermore, common standard

crimp type. The solder type has a cup in which the wire

automotive electrical components in the supply system

is held by solder permanently, whereas the solderless

such as headlight, taillight, and stoplight switch

type is connected to the wire by special tools that deform

assemblies are marked with these standard wire

the barrel of the terminal and exert pressure on the wire

numbers. Therefore, these numbers should be used to

to form a strong mechanical bond and electrical

the maximum extent

connection. Solderless-type terminals gradually have

replaced solder-type terminals in military equipment.

b. Solderless Terminals (Fig. 17-36).

Solderless terminals come in a variety of designs. Some

of the more common recommended terminals are the

ring-tongue, rectangular-tongue, and flag types. One of

the major sources of trouble when a terminal is

connected to a wire has always been the breakage of the

wire near its junction with the terminal. Wire failures

have been decreased by adding a sleeve to the basic

terminal. The inside diameter of the sleeve is slightly

larger than the outside diameter of the wire

insulation. In the crimping operation, when the

Figure 17-35. Wire Identification.

TA233645

17-28

|

||

|

||