| Tweet |

Custom Search

|

|

|

||

TM 9-8000

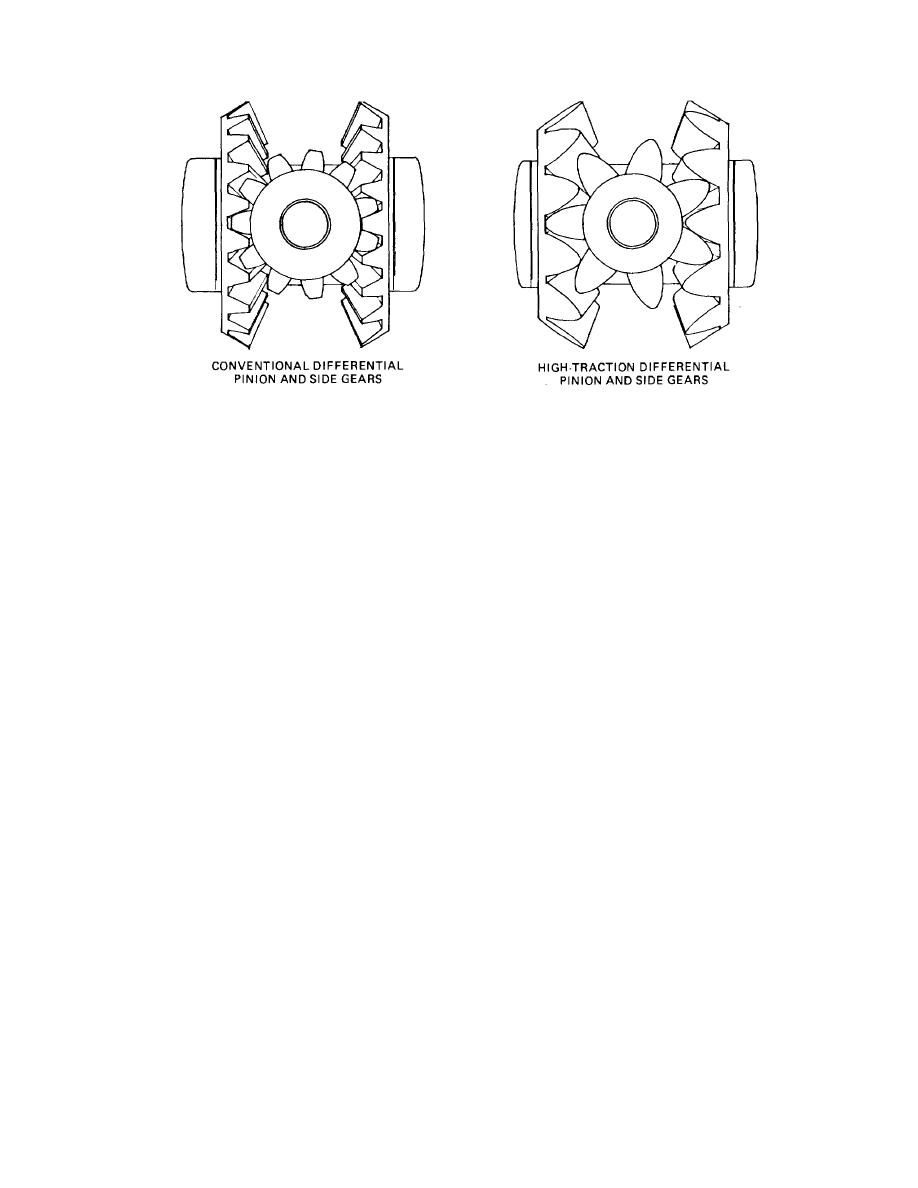

Figure 29-3. Comparison of Conventional and High-Traction Differential Gears.

on one wheel and less on the other as the pinions move

one wheel encounters a slippery spot and loses traction

around, until both wheels start to rotate at the same

while the other wheel is on a firm spot and has traction.

speed. When this occurs, the relative motion between

It will not work, however, when one wheel loses traction

completely. In this respect, it is Inferior to the differential

wheel is again equal. This device assists considerably In

lock.

starting the vehicle or keeping it rolling In cases where

Section II. NO-SPIN DIFFERENTIALS

clutch member remains fully engaged with the spider

29-4. Purpose. To provide a means of improving

clutch teeth. The spider clutch teeth (the driving teeth)

tractive effort at the driving wheels when one wheel

drive the right (inside) wheel at differential drive ring gear

tends to slip from loss of traction, It is necessary that the

speed.

The left wheel (outside) covers a greater

differential prevent actual slippage and supply torque to

distance and must turn faster than differential drive ring

the driving wheels only to the extent that the wheels can

gear speed. The differential must permit this action

utilize the torque without slipping.

The no-spin

because, as the left wheel begins to turn faster, the left-

differential does this by using various types of clutches

driven clutch member also turns faster than differential

between the driving axles.

drive ring gear and spider speed. As the left-driven

clutch member begins to turn faster, the cam lobes or

29-5. Sprag-Type No-Spln Differential (Fig. 29-

ramps on its edge ride up on the cam lobes on the center

4). The sprag-type no-spin differential does not contain

cam. This action pushes the left-driven clutch member

pinion gears and side gears as does the conventional

away from the spider so the clutch teeth disengage. As

differential. Instead, it consists essentially of a spider

the crest of the ramp is passed, spring pressure forces

attached to the differential drive ring gear through four

the teeth of the driven clutch member back Into full

trunnlons, plus two driven clutch members with side

engagement with the teeth on the spider. But the action

teeth that are indexed by spring pressure with side teeth

is repeated as long as the left wheel turns more rapidly

In the spider. Two side members are splined to the

than the right wheel. Full drive is applied to the right

wheel axles and, In turn, are splined into the driven

wheel; no drive is applied to the left wheel. But as soon

clutch members.

as the vehicle completes the turn and the left wheel

slows down to right wheel speed, driving power is applied

a. Operation in Turning. The center

cam in the

equally to

spider is held in place by a snap ring that

permits the

TA233779

center cam to rotate but does not permit

it to move

laterally. When making a right turn, the

right-driven

29-3

|

||

|

||