| Tweet |

Custom Search

|

|

|

||

TM 9-8000

both. For a left turn, the action is similar except that full

other no-spin differential. The teeth are separated so

drive is applied to the left wheel; the right wheel turns

that no driving can take place. In this unit, however, the

more rapidly than the left wheel.

teeth do not index repeatedly because the rotatable cam,

left slightly behind, prevents this. The ramps on the

b. Tractive Effort. With this differential, one wheel

rotatable cam are halfway between the ramps on the

fixed cam of the driven clutch member. The staggered

cannot spin because of loss of tractive effort and thereby

ramps will not permit teeth engagement. As soon as the

deprives the other wheel of driving effort. For example,

turn is completed, the driven clutch member slows down

one wheel is on ice and the other wheel is on dry

to spider speed, the ramps realign, and teeth

pavement. The wheel on ice is assumed to have no

engagement takes place. Where a vehicle has a tandem

traction. However, the wheel on dry pavement will pull to

driving axle unit or multiple axles, a no-spin differential

the limit of its tractional resistance at the pavement. The

may be placed in the transfer case between the output

wheel on ice cannot spin because wheel speed is

shafts to the driving axles. The differential prevents loss

governed by the speed of the wheel applying tractive

of tractive effort from slippage or tractive loss of one set

effort.

of wheels. Also, it tends to balance torque and prevents

interaxle trapped torque, which reduces total tractive

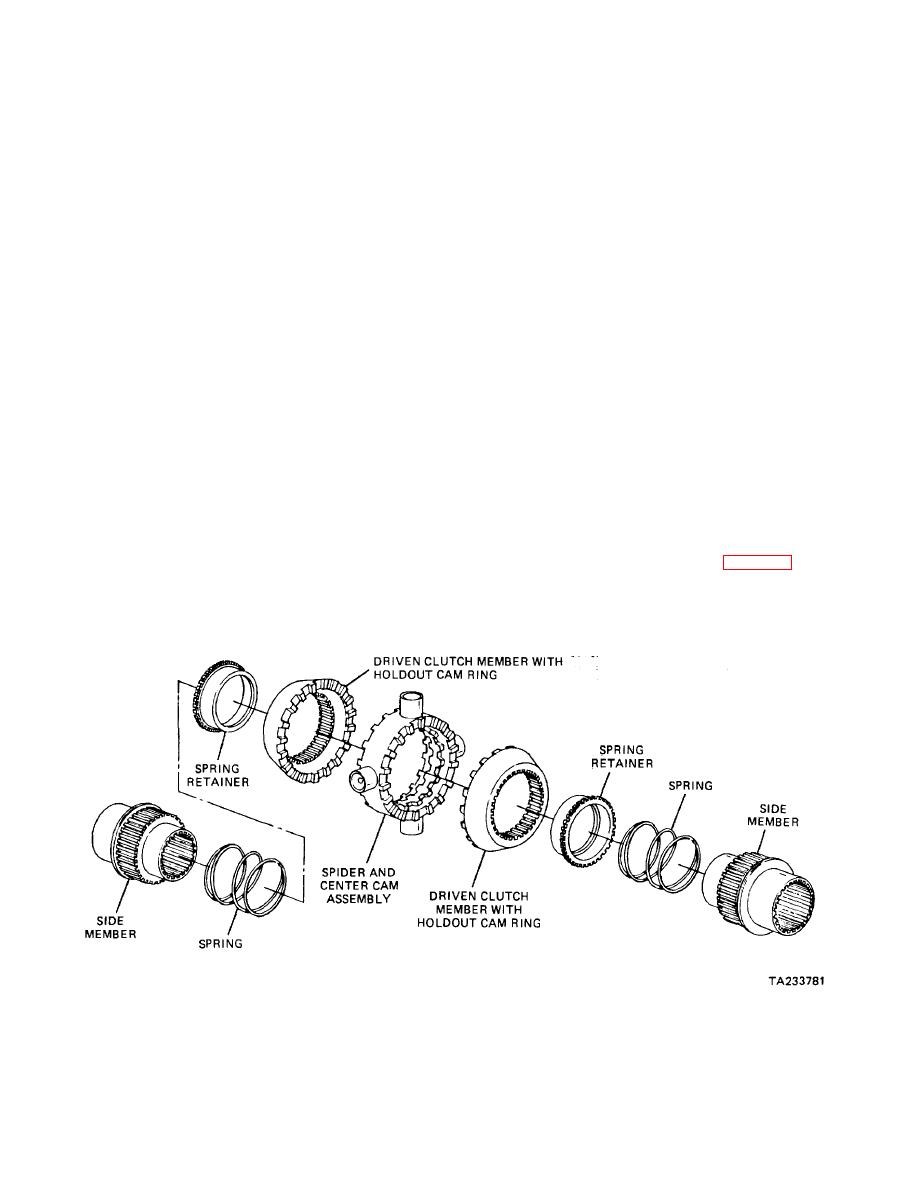

29-6. Silent-Type No-Spin Differential (Fig. 29-

effort.

5). In the silent-type no-spin differential, the construction

is very similar to the unit described above. However, the

29-7.

Clutch-Type No-Spin Differential.

center cam has wider teeth to carry the two sets of cams

in each driven clutch member. One set is fixed, the

other is able to rotate in one direction or the other a few

a. General. The clutch-type no-spin differential

degrees with respect to the fixed set. The rotatable or

holdout cam ring is slotted, and a key in the spider fits

one drive wheel experiences uncontrolled slippage. The

this slot to limit the independent rotation of the cam. The

clutch configurations that are used commonly are the

key also limits the rotation of the center cam. In

cone or the multiple plate type.

operation, when one wheel is turning faster than the

other (as in rounding a turn), the faster-turning splined

b. Multiple Plate Clutch Type (Fig. 29-6). This type

side member and driven clutch member cause the

of no-spin differential uses four side gear pinions on two

ramps on the center cam and driven clutch member cam

shafts that are at right angles to each other. The shafts,

to push the driven clutch member away from the spider.

which are V-shaped on

This action is similar to that described above for the

Figure 29-5. Silent-Type No-Spin Differential.

29-5

|

||

|

||