| Tweet |

Custom Search

|

|

|

||

TM 9-8000

opposite sides of the piston. In the open position, the

frictional resistance which retards the movement of the

valve spool is preloaded by the spring against a hollow

road wheels.

sleeve stop.

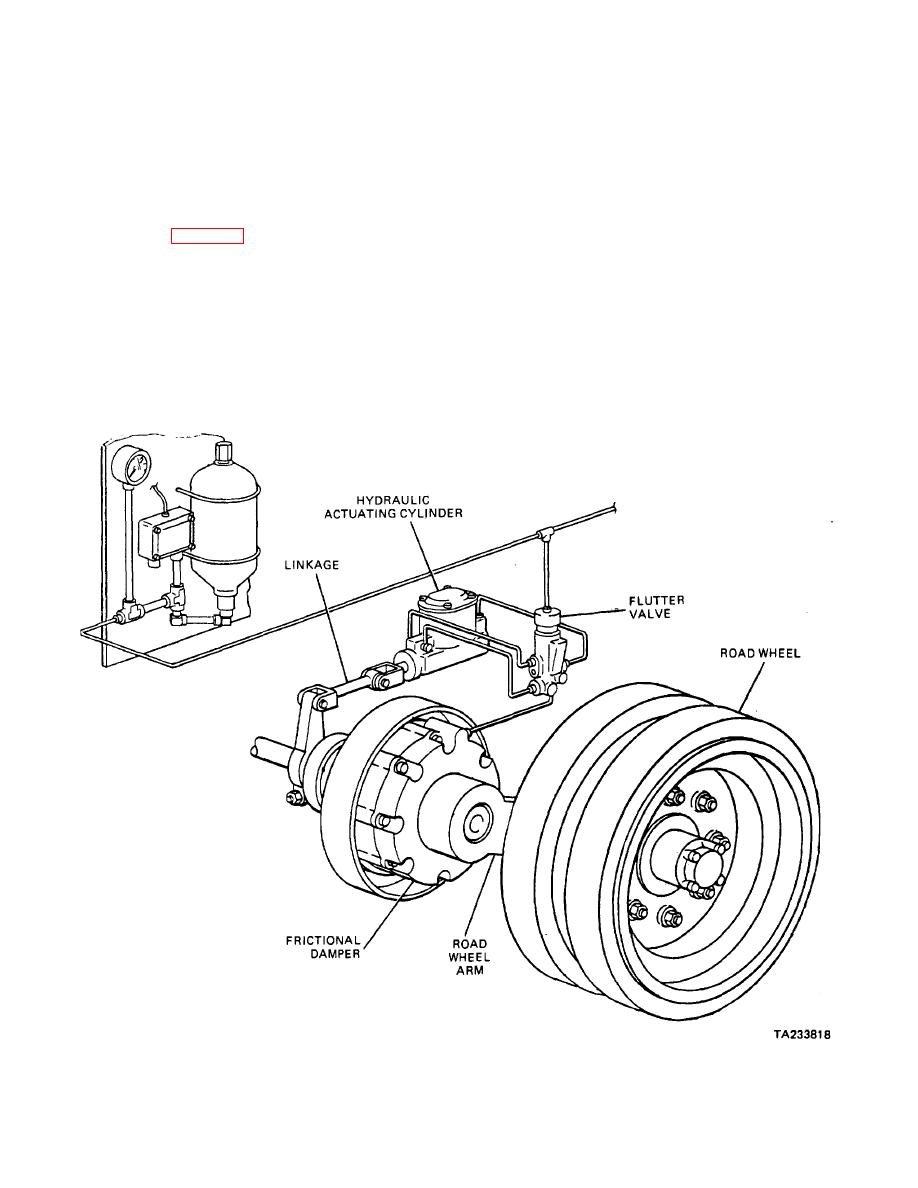

b. Construction. The hydromechanical lock-out

system is constructed of the following:

31-10. Hydromechanical Lockout System.

(1) The system uses linkage to connect the

a. Operating Principles. The hydromechanical

road wheel arm to the hydraulic actuating cylinder.

lockout system (fig. 31-5) is a suspension-damping

device that incorporates a suspension lockout. Basically,

(2) The actuating cylinder controls the rate of

the damping device is a frictional damper (disk brake) to

damping the system will produce.

which a hydraulic actuating cylinder is added. The

hydraulic-actuating cylinder or brain box supplies and

(3) The flutter valve directs the pressurized fluid

controls the pressure to the frictional damper where the

to the pistons in the frictional damper.

energy absorption takes place. As the road wheel

moves up or down, the brain box develops pressure

(4) The frictional damper contains the frictional

through the use of a piston rod, which is connected to

plates, which, when compressed, resist the movement of

the road wheel arm through linkage. The pressure

the road wheel arm.

developed is routed to the frictional damper. which

forces the stators and rotors together, creating a

Figure 31-5. Hydromechanical Lockout System.

31-6

|

||

|

||