| Tweet |

Custom Search

|

|

|

||

TM 9-8000

larger at one position than another and therefore the road

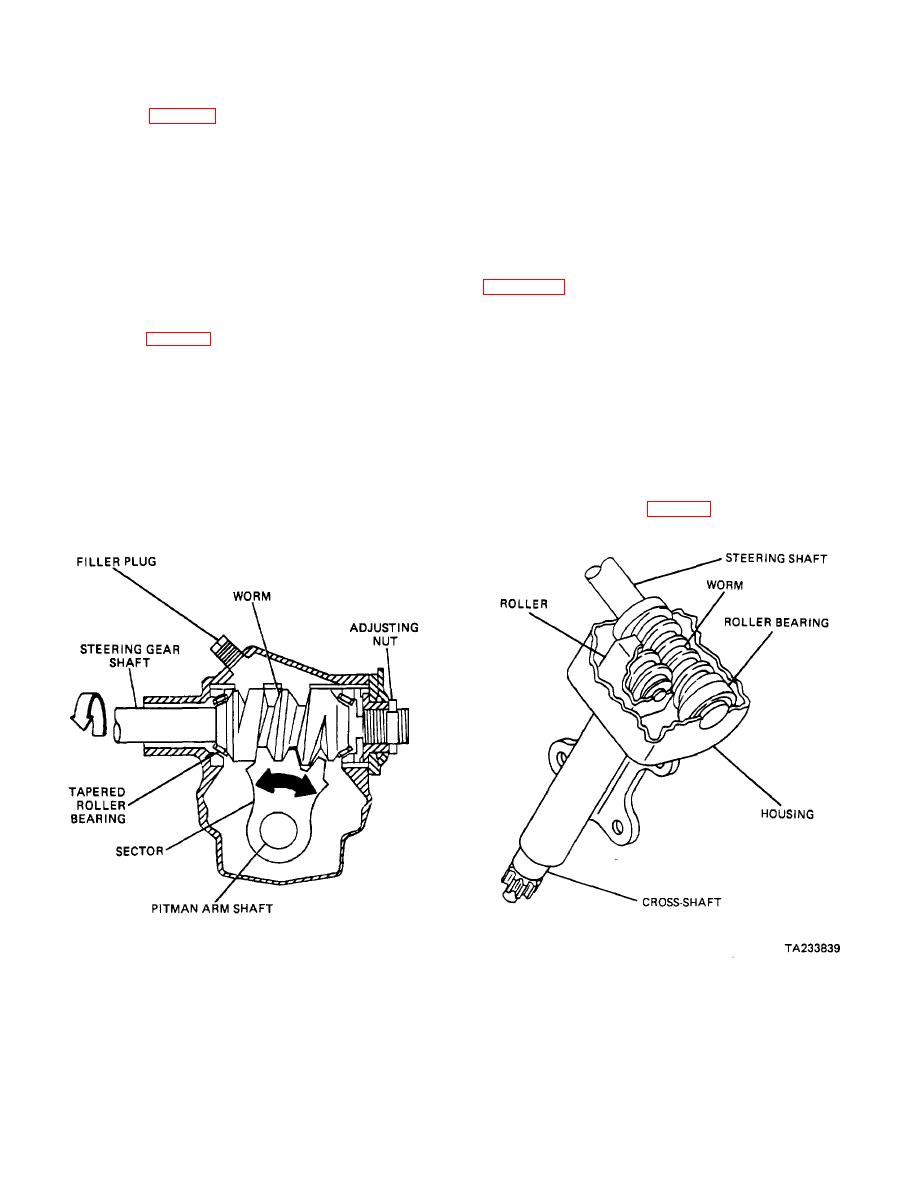

Section II. 33-4.Worm andSectorType.In the worm and sector

wheels are turned faster at certain positions than at

steering gear (fig. 33-7) the pitman arm shaft carries a

others. At the center or straight ahead position, the

gear that meshes with the worm on the steering gear

steering gear ratio is high, giving more steering control.

shaft. Generally, only a sector of a gear is used because

However, as the wheels are cramped or turned to the

it turns through an arc of approximately 70 degrees. The

side, the ratio decreases so that the action is much more

steering wheel turns the worm on the lower end of the

rapid. This design is very helpful for parking or for

steering gear shaft, which rotates the sector and the

maneuvering the vehicle.

pitman arm through the use of the shaft. The worm is

assembled between tapered roller bearings that take

33-6. Cam and Lever Type. A cam and lever steering

both thrust and load. An adjusting nut or plug is provided

gear in which the worm is known as a cam, is shown in

for adjusting the end play of the worm. Some means of

adjusting the end play of the cross-shaft also is provided.

inner end. This lever carries a stud that engages with the

cam. The stud may be integral or mounted on roller

33-5. Worm and Roller Type. The worm and roller

steering gear (fig. 33-8) is quite similar to the worm and

steering. As the steering wheel is turned, the stud moves

sector type except that a roller is supported by ball or

up and down on the cam and carries the lever with it to

roller bearings within the sector mounted on the pitman

rotate the pitman arm shaft. The pitch of the cam is not

arm shaft. These bearings assist in reducing sliding

constant, therefore the lever moves more rapidly as it

friction between the worm and sector. As the steering

nears either end of the cam. Maximum leverage occurs

wheel turns the worm, the roller turns with it but forces

at the straight ahead position when the stud engages the

the sector and the pitman arm shaft to rotate. The

fine pitch section of the cam. This makes the initial

hourglass form of worm, which tapers from both ends to

turning of the wheels easier. Therefore, a variable ratio

the center, affords better contact between the worm and

is obtained with cam and lever steering. A twin lever

roller at all positions. It provides a variable ratio to permit

provided with two studs (fig. 33-9) is used on a design for

faster and more efficient steering. Variable ratio means

heavier vehicles

that the ratio is

Figure 33-7. Worm and Sector Steering Gear

Figure 33-8. Worm and Roller Steering Gear

33-6

|

||

|

||