| Tweet |

Custom Search

|

|

|

||

TM 9-8000

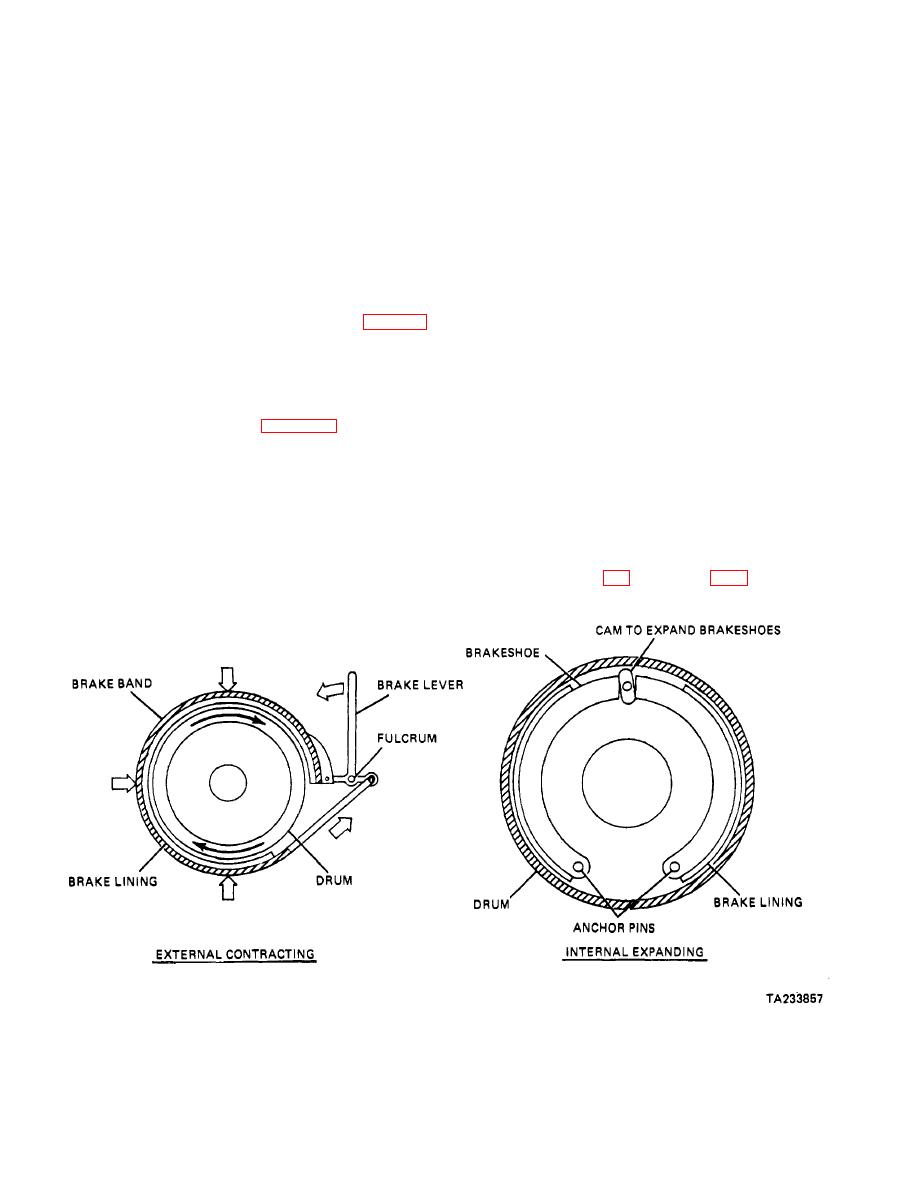

Section II. DRUM BRAKE MECHANISMS

commonly is used because it is cheaper to produce In

34-6. Rotating and Nonrotating Units. There are

large quantities. Steel shoes expand at about the same

many types of brake system designs In use on modern

rate as the drum when heat Is generated by brake

automotive vehicles. Regardless of the design, all

application, thereby maintaining the clearance between

systems require the use of a rotating and nonrotating

the brakedrum and brakeshoe under most conditions.

unit. Each of these units houses one of the braking

The brake lining Is riveted or bonded to the face of the

surfaces, which, when forced together, produce the

brakeshoe and makes contact with the Inner surface of

friction required for braking action. The rotating unit on

the brakedrum. Semitubular brass rivets sometimes are

many motor vehicle wheel brakes consists of a drum that

used to attach the brake lining to the brakeshoe. The

is secured to and driven by the wheel. The nonrotat- Ing

brass rivets are chosen over other types because brass

unit consists of the brakeshoes and linkage required to

does not score the drums excessively if the lining should

apply the shoes to the drum. Brakes may be of the

be neglected and worn past the point of replacement.

internal expanding or external contracting type (fig. 34-5),

Aluminum rivets are not used because they may corrode

depending on how the stationary surface is forced

due to moisture. The brake lining also may be bonded

against the rotating surface.

directly to the brakeshoe. In this process, a special

cement Is used to adhere the lining to the brakeshoe.

34-7. Construction.

After application, the shoe Is baked at a predetermined

temperature to ensure proper setting of the cement. In

a. Brakeshoes. Brakeshoes (fig. 34-6) are used to

some brake assemblies, the lining Is not fastened to

support, strengthen, and move the brake lining. Because

either the shoe or the drum, but floats between them and

the brake lining material Is soft and brittle, it Is necessary

Is held by a lining retainer on one side and the brake

to add a supportive foundation to the lining so it will not

shield on the other.

collapse and break during use. The brakeshoes also

serve to attach the brake lining to a stationary member,

b. Brake Lining. Variation in brake design and operating

usually the backing plate, so the braking action may be

conditions make it necessary to have different types of

accomplished. Brakeshoes are made of malleable Iron,

brake linings. Brake linings come In woven and molded

cast steel, drop-forged steel, pressed steel, or cast

form

The

aluminum.

Pressed

steel

Figure 34-5. Internal Expanding and External Contracting Brakes

34-4

|

||

|

||