| Tweet |

Custom Search

|

|

|

||

TM 9-8000

from the brake line connection between the pistons. At

the top of the cylinder, between the pistons, Is a bleeder

hole through which air is released when the system is

filled with brake fluid. A stepped wheel cylinder (B, fig.

the front shoe than on the rear shoe, due to self-

energizing action. By using a larger piston for the rear

shoe, the shoe receives more pressure to offset the self-

energizing action on the front shoe. This requires a

stepped wheel cylinder with two bore sizes. If it is desired

that both shoes be independently self-energizing,

especially on the front wheels, it Is necessary to have

two wheel cylinders, one for each shoe. Each cylinder

has a single piston (C, fig. 34-22), and is mounted on the

opposite side of the brake backing plate from the other

cylinder. Such an arrangement is shown In figure 34-9.

3427. Hill Holder. The hill holder provides greater

ease of vehicular control on hills and in traffic. The

device Is connected to the clutch pedal and keeps the

brakes applied as long as the clutch pedal Is depressed

when the car is on an upgrade, even after the brake

pedal Is released. The driver then Is able to use his or

her right foot for the accelerator pedal.

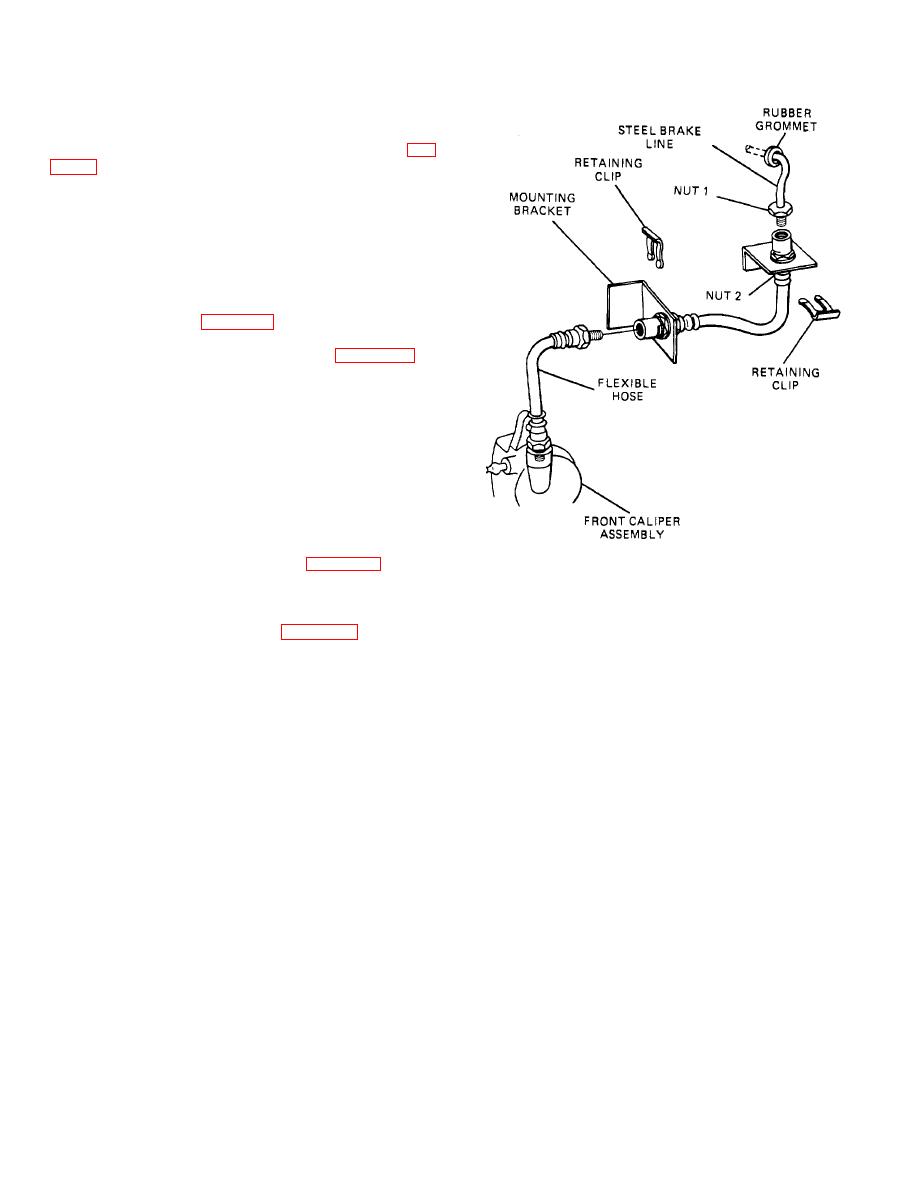

34-28. Brake Lines. The brake lines transmit fluid under

pressure from the master cylinder to the wheel cylinders.

High-quality double thick steel tubing (fig. 34-23) is used

Figure 34-23. Brake Lines.

where no flexing is involved. The tubing also is copper

plated and coated with lead to prevent rust and

fluid must be well above the temperatures encountered

corrosion. Due to the relative movement of the

during the most severe brake application on the hottest

suspension, a high-pressure hose (fig. 34-23) is used to

day and also maintain an even viscosity at extreme cold

transmit fluid to each front wheel brake assembly and to

temperatures. The brake fluid must be able to absorb

the components on the rear axle(s). Mounting brackets

and hold moisture and also act as a lubricant.

also are used where flex hoses connect to solid hoses.

The mounting brackets help hold the assemblies secure

a. Standard Fluid. Standard brake fluid is composed

and reduce vibration, which may cause metal fatigue.

chiefly of equal parts of alcohol and caster oil. This

combination of fluids worked well under normal

34-29. Brake Fluid. Hydraulic brake fluid is the liquid

conditions but boiled easily and became a vapor under

medium In the brake system used to transmit fluid

heavy-duty application. Standard fluid also tends to

motion and pressure to the wheel brake components.

separate into components when exposed to low

The hydraulic brake fluid used in today's modern

temperatures. The Increasing requirements of brake fluid

vehicles must have some important properties; the most

led to the development of silicone brake fluid

important are discussed below. The fluid must remain a

liquid during all operating temperatures. The boiling point

b. Silicone Brake Fluid. After 40 years of research and

of the

development, a brake fluid that was acceptable under

extreme operating conditions was developed. This fluid

achieved low water pickup and good corrosion

protection. The fluid also provides good lubrication

qualities and rubber compatibility. Silicone brake fluid

has been used in all military vehicles since the end of

1982.

TA233875

34-28

|

||

|

||