| Tweet |

Custom Search

|

|

|

||

TM 9-8000

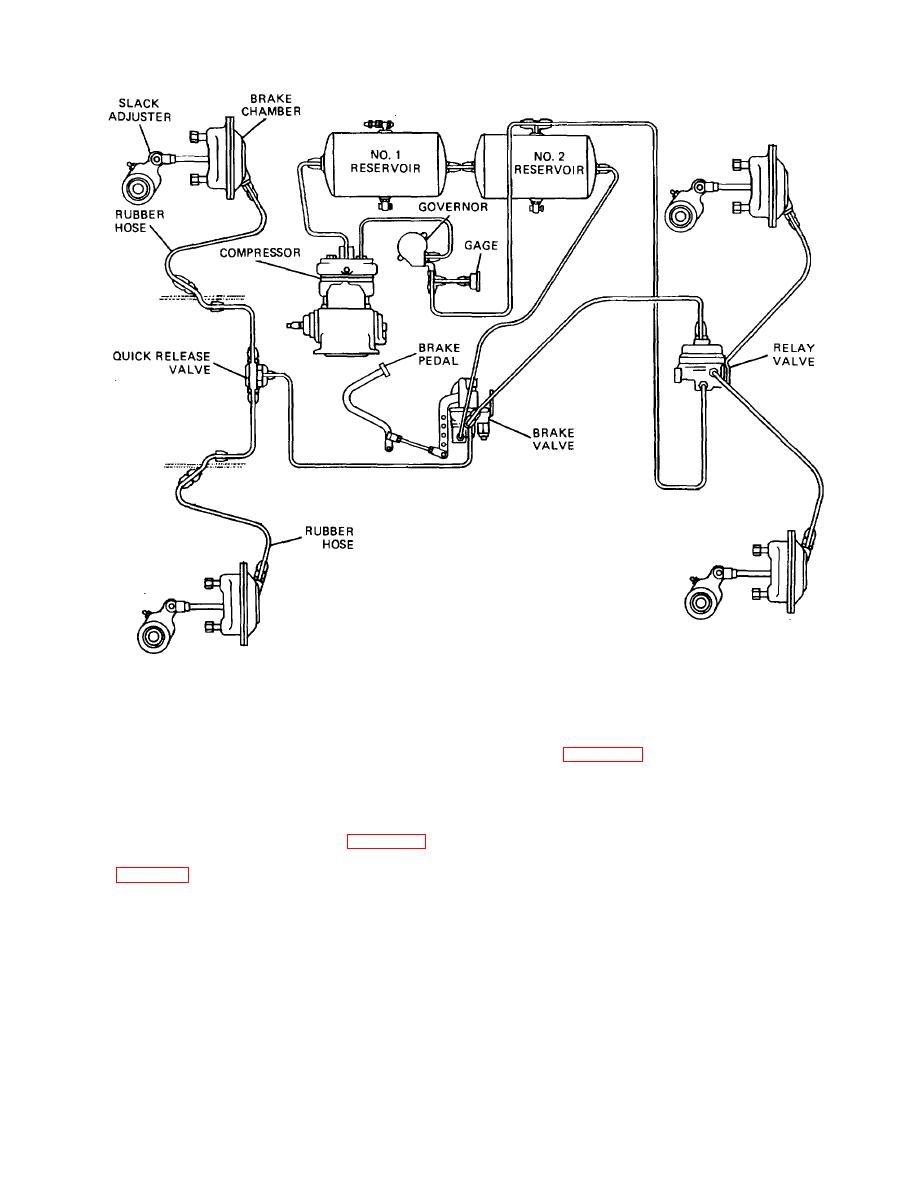

Figure 34-31. Typical Airbrake System.

compressed. The pressure developed lifts the discharge

34-39. System Components.

valve and the compressed air is discharged to the

reservoirs (fig. 34-32). The discharge valve closes as

a. Air Compressor. Air compressors usually are

soon as pressure Is relieved when the piston starts its

single-acting reciprocating units, either self-lubricated

downstroke.

or lubricated from the vehicle engine lubricating system.

Both water-cooled and air-cooled cylinder heads are

used. Compressors having a displacement of

b. Unloader. When the reservoir air pressure reaches

approximately 7 cfm have two cylinders (fig. 34-32),

the maximum setting of the governor, air under pressure

while those with a displacement of 12 cfm have three

is allowed by the governor to pass into a cavity below an

cylinders (fig. 34-33).

unloading diaphragm in the cylinder head. This air

pressure lifts one end of the unloading lever, which

The air compressors operate continuously while the

pivots on its pin and forces the unloading valves off their

engine is running, but the actual compression of air is

seats. With the unloading valves off their seats, the

controlled by the governor.

unloading cavity forms a passage between the cylinders

above the pistons. Air then passes back and forth

With a partial vacuum created on the piston downstroke,

through the cavity between the cylinders and

intake ports are uncovered near the bottom of the stroke.

compression is stopped. A drop in air pressure below the

Intake ports are covered as the piston starts its upstroke.

minimum setting of the governor causes

Air in the cylinder is

TA233880

34-34

|

||

|

||