| Tweet |

Custom Search

|

|

|

||

3500 ENGINE

SPECIFICATIONS

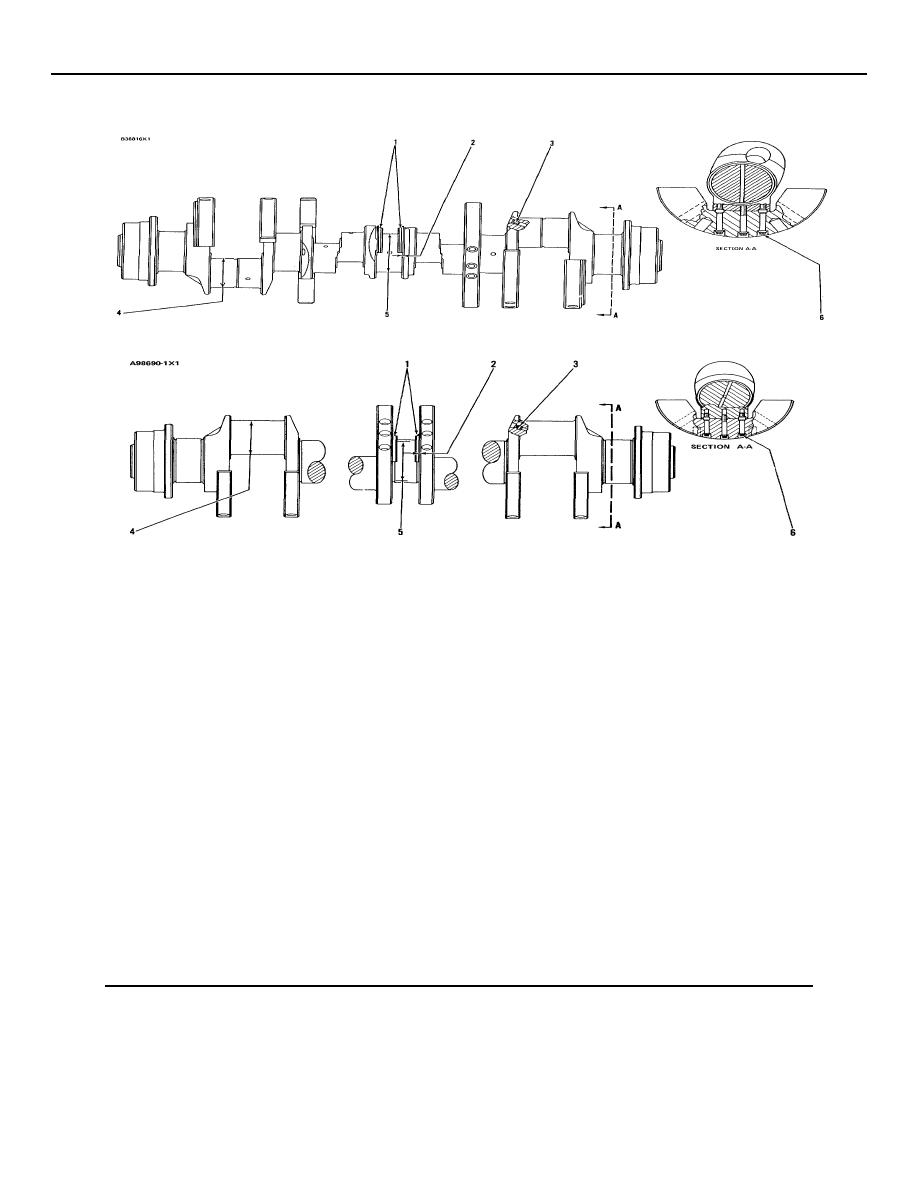

CRANKSHAFT

(3508)

(3512 & 3516)

(1)

Thrust plates for center bearing only.

(5)

Make reference to Main Bearing Journals.

(2)

End play for the crankshaft

(new)

...... 0.170 to 0.630 mm (.0067 to

(6)

Procedure to tighten counterweight bolts:

.0248 in.)

a.

Before assembly, put Fel-Pro C100

(3)

Plugs.

Lubricant (if not available, use 2P2506

Thread Lubricant) on the bolt threads,

Earlier:

shank, and underside of bolt head.

5

Torque for 1/4 pipe thread

b.

Tighten the bolts evenly to .........

50

Nm (37 4 lb. ft.)

plugs

....... 25 Nm (20 lb. ft.) min

"Stake" (make a mark with a punch) the

Tighten each bolt more ......... 120 5

c.

crankshaft to hold the pipe plugs tight.

NOTICE

Later:

Each counterweight has a number and must be

installed in the same position as the correct number

Torque for straight thread

on the crankshaft mounting pad to prevent damage

....... 50 7 Nm (37 5 lb. ft.)

plugs

to the crankshaft when the engine is run.

(4)

Make reference to Connecting Rod Bearing

Journals.

NOTE: FOR TORQUE VALUES NOT GIVEN, SEE THE FIRST PAGE OF SPECIFICATIONS FOR

GENERAL TIGHTENING TORQUES

39

|

||

|

||