| Tweet |

Custom Search

|

|

|

||

FUEL SYSTEM

SYSTEMS OPERATION

FUEL FLOW THRU INJECTOR

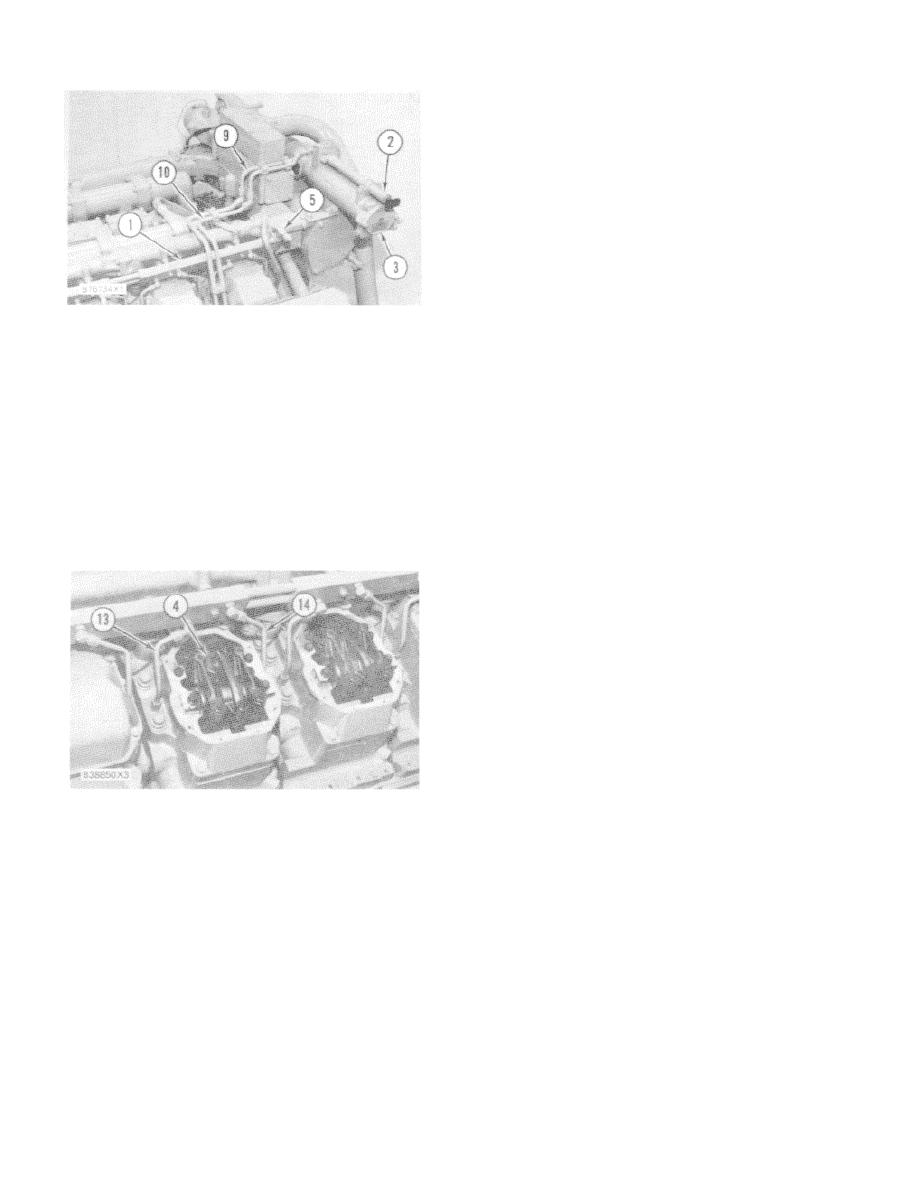

4. Injector. 13. Outlet fuel line. 14. Inlet fuel line.

15. Drilled passage. 16. Cylinder head. 17. Cylinder.

Check each engine installation for an excess fuel

flow based on fuel consumed (used for combustion).

Minimum flow is three times the amount of fuel

consumed. Excess fuel is then returned to the fuel tank,

not back to the pump inlet. This will make sure that any

air in the system will be removed before the fuel is sent

back to the injectors.

RIGHT SIDE OF ENGINE

1. Fuel manifold (right hand). 2. Priming pump. 3.

Pressure regulating valve (2) has a spring and

Fuel filter housing. 5. Pressure regulating valve. 9.

plunger arrangement between the bottom section of the

Fuel line to filter housing (from transfer pump). 10.

fuel manifolds and the line that returns fuel to the tank.

Fuel line to priming pump (from transfer pump).

This valve keeps the pressure of the fuel at 415 to 450

kPa (60 to 65 psi) in the cylinder heads and fuel

ed to the right side of each cylinder head. On earlier

manifolds. The valve also has resistance to fuel flow but

engines, filter screens are located in the fittings where

little resistance to air. This helps re- move (bleed) air

fuel goes into each cylinder head. On later engines, the

from the fuel injection system when the engine is in

filter screens are located in the ports of the unit injector.

operation. The air is returned to the fuel tank and vented

A drilled passage (15) in cylinder head (16) takes fuel to

to the atmosphere.

a circular (shape of a circle) chamber around the

injector. The chamber is made by O-rings on the outside

A small orifice connects the inlet and outlet

diameter of injector (4) and the injector bore in the

passages in the adapter (housing) of pressure regulating

cylinder head.

valve (2). The orifice is used as a syphon break when

the fuel filters are changed. This keeps the fuel lines and

manifolds from being drained and the use of fuel priming

pump (4) is not normally needed. The fuel priming pump

must be used when the lines are dry. For example: after

an overhaul or other major fuel system work.

CYLINDER HEADS

3. Fuel injector. 13. Outlet fuel line. 14. Inlet fuel

line.

Only part of the fuel in the chamber is used for injection.

Approximately 4/2 times as much fuel as needed for

normal combustion flows through the chamber to a

drilled passage in the left side of the cylinder head. This

passage is connected by outlet fuel line (13) to the

bottom section of the fuel manifold. This constant flow of

fuel around the injectors helps to cool them.

The fuel flows back through the bottom section

of each fuel manifold to pressure regulating valve (2), on

the front of the right fuel manifold. The fuel flows

through this valve and then back to the tank.

66

|

||

|

||