| Tweet |

Custom Search

|

|

|

||

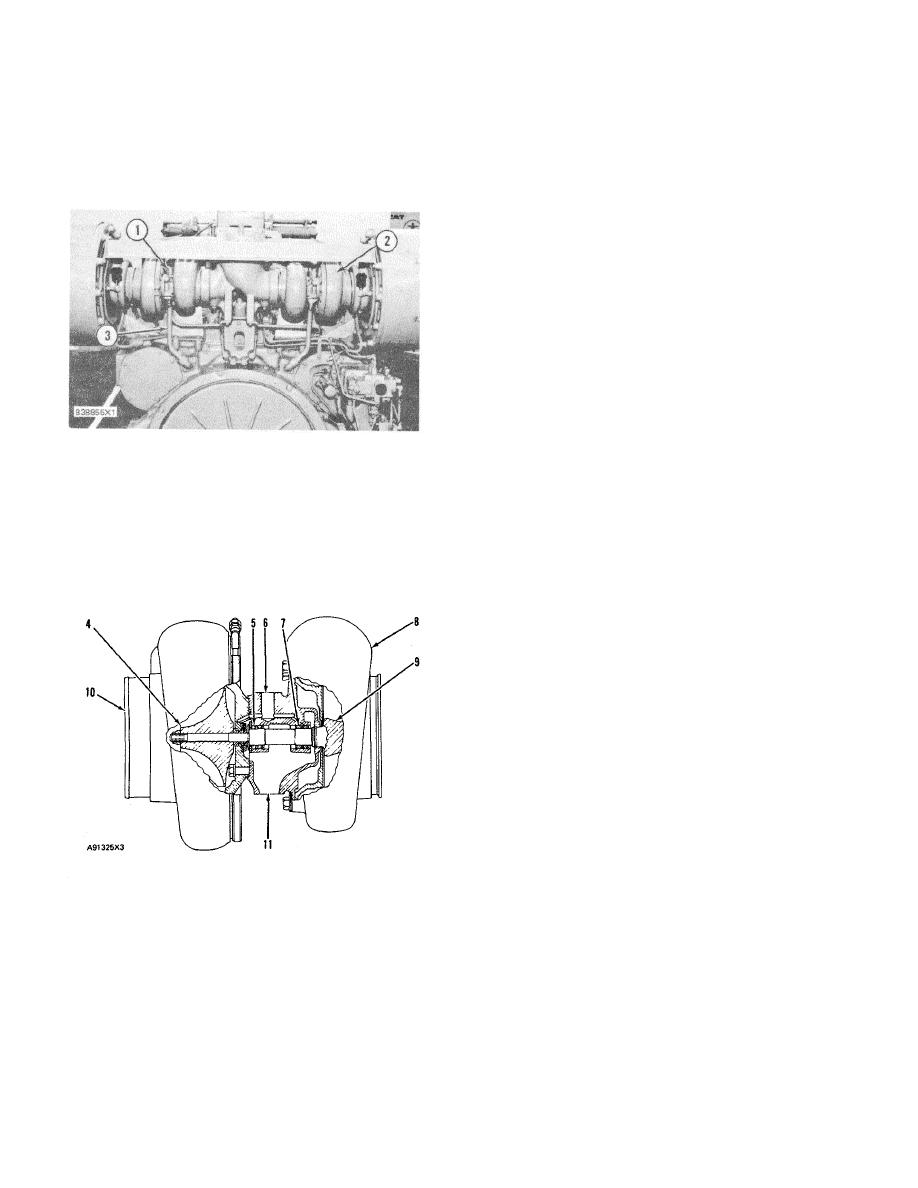

AIR INLET AND EXHAUST SYSTEM

SYSTEMS OPERATION

(3512 Shown)

TURBOCHARGERS

4. Compressor wheel. 5. Bearing. 6. Oil Inlet. 7.

Bearing. 8. Turbine housing. 9. Turbine wheel. 10. Air

There are two turbochargers, on the rear of the

in-let. 11. Oil outlet.

engine. The turbine side of the turbochargers is fastened

Clean air from the air cleaners is pulled through

turbocharger is connected to the aftercooler.

the compressor housing air inlet (10) by rotation of

compressor wheel (4). The action of the compressor

wheel blades causes a compression of the inlet air. This

compression gives the engine more power because it

makes it possible for the engine to burn additional fuel

with greater efficiency.

Maximum rpm of the turbocharger is controlled

by the fuel setting, the high idle rpm setting and the

height above sea level at which the engine is operated.

NOTICE

If the high idle rpm or the fuel setting is higher than

given in the Fuel Setting And Related Information

TURBOCHARGERS

Fiche (for the height above sea level at which the

1. Turbocharger. 2. Oil drain line. 3. Oil supply line.

engine is operated), there can be damage to engine

or turbocharger parts. Damage will result when

The exhaust gases go into turbine housing (8)

increased heat and/or friction due to the higher

and push the blades of turbine wheel (9). This causes

engine output goes beyond the engine cooling and

the turbine wheel and compressor wheel to turn at up to

lubrication systems abilities. A mechanic that has

70,000 rpm.

the proper training is the only one to make the

adjustment of fuel setting and high idle rpm setting.

The bearings (5 and 7) in the turbocharger use

engine oil under pressure for lubrication. The oil comes

in through oil inlet port (6) and goes through passages in

the center section for lubrication of the bearings. Then

the oil goes out oil outlet port (11) and back to the oil pan.

VALVE SYSTEM COMPONENTS

The valve system components control the flow of

inlet air and exhaust gases into and out of the cylinders

during engine operation.

The crankshaft gear drives the camshaft gears

through idlers. Both camshafts must be timed to the

crankshaft to get the correct relation between piston and

valve movement.

TURBOCHARGER

78

|

||

|

||