| Tweet |

Custom Search

|

|

|

||

4AIR STARTING SYSTEM

SYSTEMS OPERATION

AIR STARTING SYSTEM

temperatures below 0C (32F)] should be used with the

The air starting motor is used to turn the engine

flywheel fast enough to get the engine running.

starting system. The maximum pressure for use in the

air starting motor is 1030 kPa (150 psi).

Higher

pressures can cause safety problems.

TYPICAL AIR STARTING SYSTEM

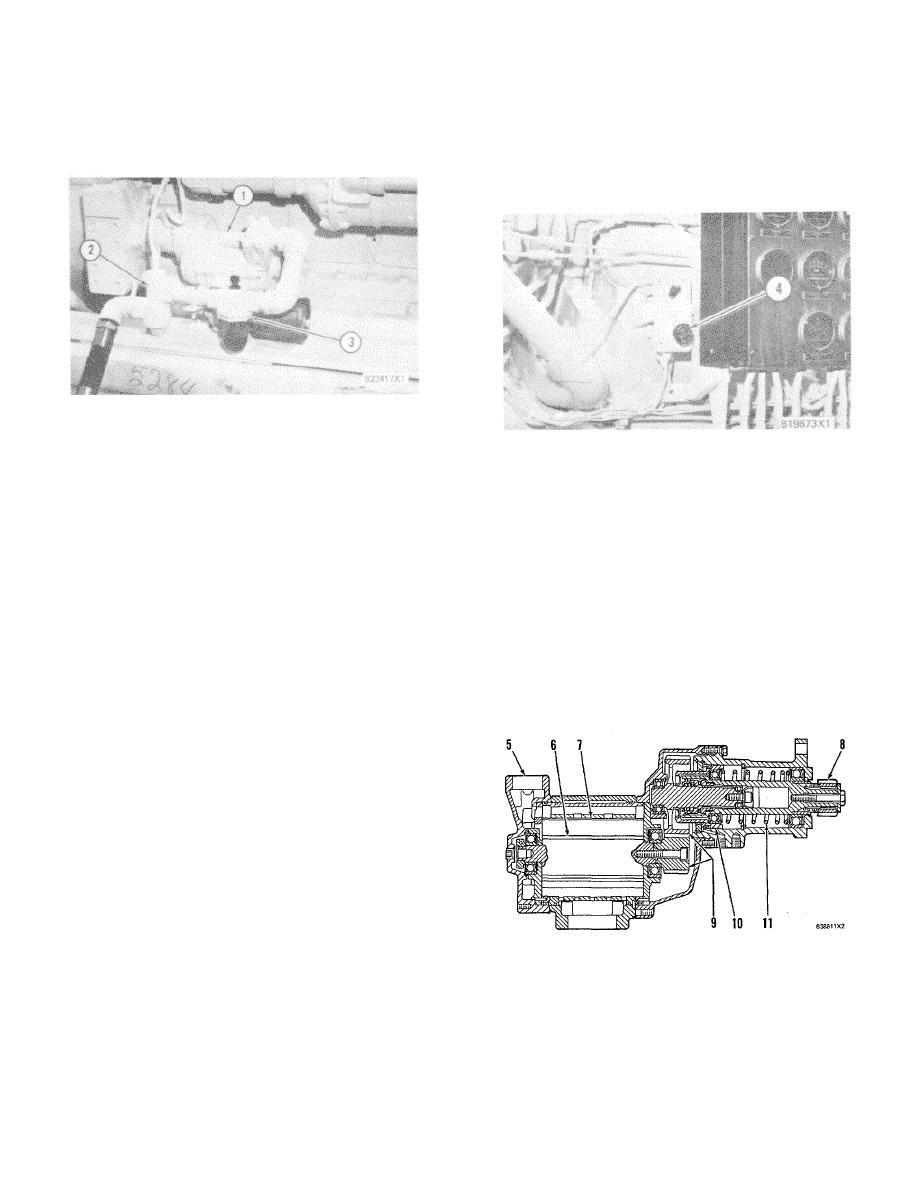

1. Air starting motor. 2. Relay valve. 3. Oiler.

TYPICAL AIR START INSTALLATION

The air starting motor can be mounted on either

4. Air start control valve.

side of the engine. Air is normally contained in a storage

tank and the volume of the tank will determine the length

The air from the supply goes to relay valve (2).

of time the engine flywheel can be turned. The storage

The starter control valve (4) is connected to the line

tank must hold this volume of air at 1720 kPa (250 psi)

before the relay valve (2). The flow of air is stopped by

when filled.

the relay valve (2) until starter control valve (4) is

activated. The air from starter control valve (4) goes to

For engines which do not have heavy loads when

piston (10) behind pinion (8) for the starter. The air

starting, the regulator setting is approximately 690 kPa

pressure on piston (10) puts spring (11) in compression

(100 psi). This setting gives a good relationship between

and puts pinion (8) in engagement with the flywheel gear.

cranking speeds fast enough for easy starting and the

When the pinion is in engagement, air can go out through

length of time the air starting motor can turn the engine

another line to relay valve (2). The air activates relay

flywheel before the air supply is gone.

valve (2) which opens the supply line to the air starting

motor.

If the engine has a heavy load which can not be

disconnected during starting, the setting of the air

pressure regulating valve needs to be higher in order to

get high enough speed for easy starting.

The air consumption is directly related to speed;

the air pressure is related to the effort necessary to turn

the engine flywheel. The setting of the air pressure

regulator can be up to 1030 kPa (150 psi), if necessary,

to get the correct cranking speed for a heavily loaded

engine. With the correct setting, the air starting motor

can turn the heavily loaded engine as fast and as long as

it can turn a lightly loaded engine.

AIR STARTING MOTOR

Other air supplies can be used if they have the

5. Air inlet. 6. Vanes. 7. Rotor. 8. Pinion. 9. Gears.

correct pressure and volume. For good life of the air

10 Piston. 11. Piston spring.

starting motor, the supply should be free of dirt and

water. A lubricator with SAE 10 nondetergent oil [for

temperatures above 0C (32F)], or diesel fuel [for

86

|

||

|

||