| Tweet |

Custom Search

|

|

|

||

FUEL SYSTEM

TESTING AND ADJUSTING

Install test plug (17) and check the adjustment of

rocker arm (10). The roller on the rocker arm must just

clear (be just above) the top of test plug (17) when the

rocker arm is moved to either the extended or retracted

position.

If an adjustment is needed, see

MAINTENANCE AND ADJUSTMENT PROCEDURES in

Special Instruction, Form No. SEHS7788. While test

plug (17) is still in position, check the tester for leaks.

See LEAK TEST FOR INJECTOR TESTER in this

section.

Operation Of The Tester

6V4022 INJECTOR TESTER

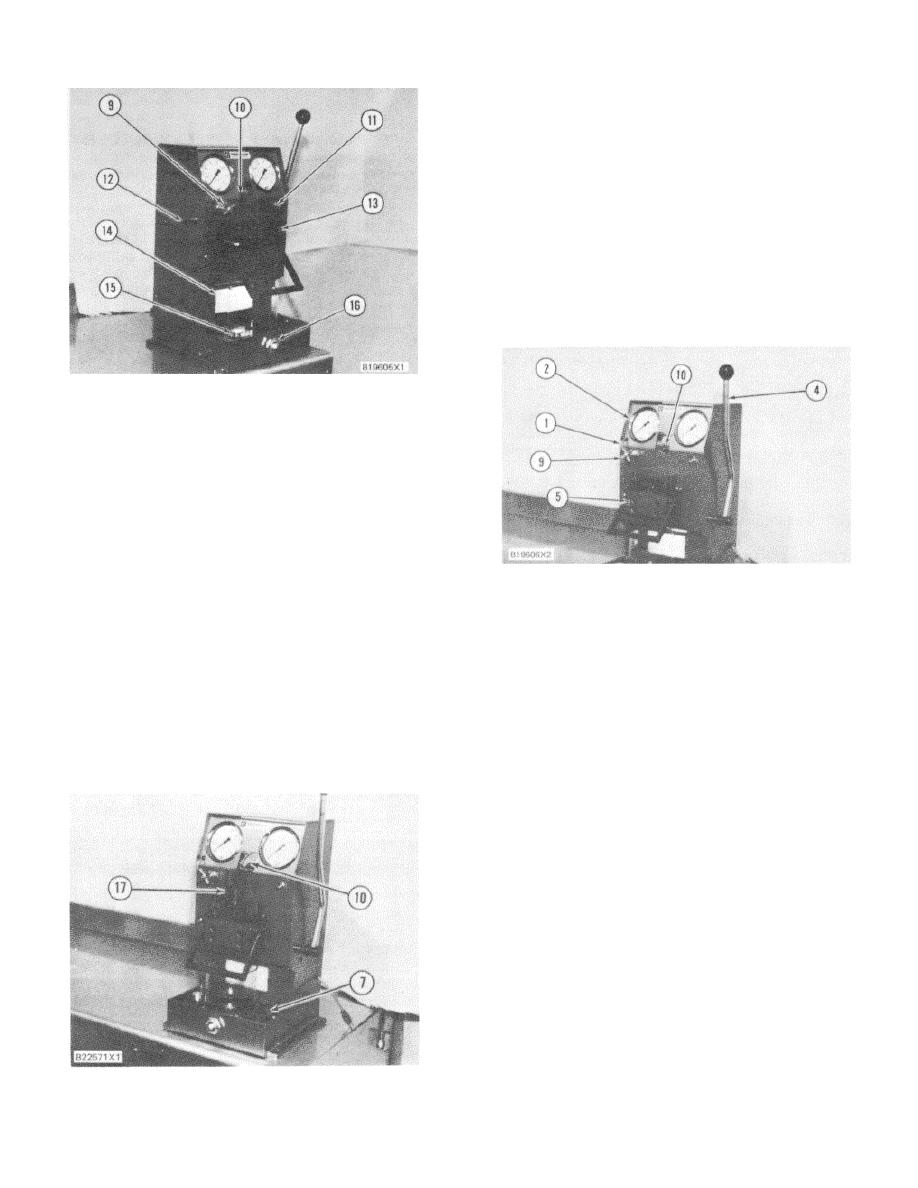

9. Test pressure valve. 10. Rocker arm. 11. Light

switch. 12. Rocker arm control lever. 13. Clamp

plate. 14. Light panel. 15. Drain cover. 16. Fluid

level indicator.

The test procedures that follow will give an

indication of injector condition. Do not use an injector in

an engine unless all test results are within the test

specifications.

TESTER NOMENCLATURE

Injector Tester Preparation

1. Sight tube. 2. Test pressure gauge. 4. Handle.

5. Injector holding block. 9. Test pressure valve.

Before a new 6V4022 Injector Tester is put to

10. Rocker arm.

use, some specific procedures must be followed to make

sure the tester will operate correctly. Remove drain

panel (7) to make sure that the test fluid reservoir is

Operation of handle (4) backward and forward

clean, and also that there is a clean filter element in its

pumps (sends) test fluid from the reservoir in the base of

correct location. Use clean SAE J-967 Calibration Fluid

the tester, through the filter element (in the base), to an

to fill the supply reservoir to its correct level. This is the

inlet check valve and an outlet check valve to test

same type and quality of test fluid as that used in a

pressure gauge (2), then down to injector holding block

Caterpillar Fuel Injection Test Bench. Be sure to put

(5). When an injector is in position in injector holding

drain panel (7) back in position after the reservoir is

block (5), the test fluid fills the injector and the chamber

filled.

around it, and is then sent to test pressure valve (9),

through sight tube (1). It then returns to the reservoir in

the base of the tester.

When test pressure valve (9) is in the "CLOSED"

position, test fluid cannot go back to the reservoir c when

handle (4) is operated. This causes high pressure in

injector holding block (5), and in the injector. This high

pressure is used to test the injector for external (outer)

leakage and leakdown rate (amount of time for pressure

drop between the specific pressure limits).

TESTER PREPARATION

7. Drain panel. 10. Rocker arm. 17. Test plug.

108

|

||

|

||