| Tweet |

Custom Search

|

|

|

||

3161 GOVERNOR

TESTING AND ADJUSTING

GOVERNOR ADJUSTMENTS

DROOP SETTING - INTERNAL

ADJUSTMENT

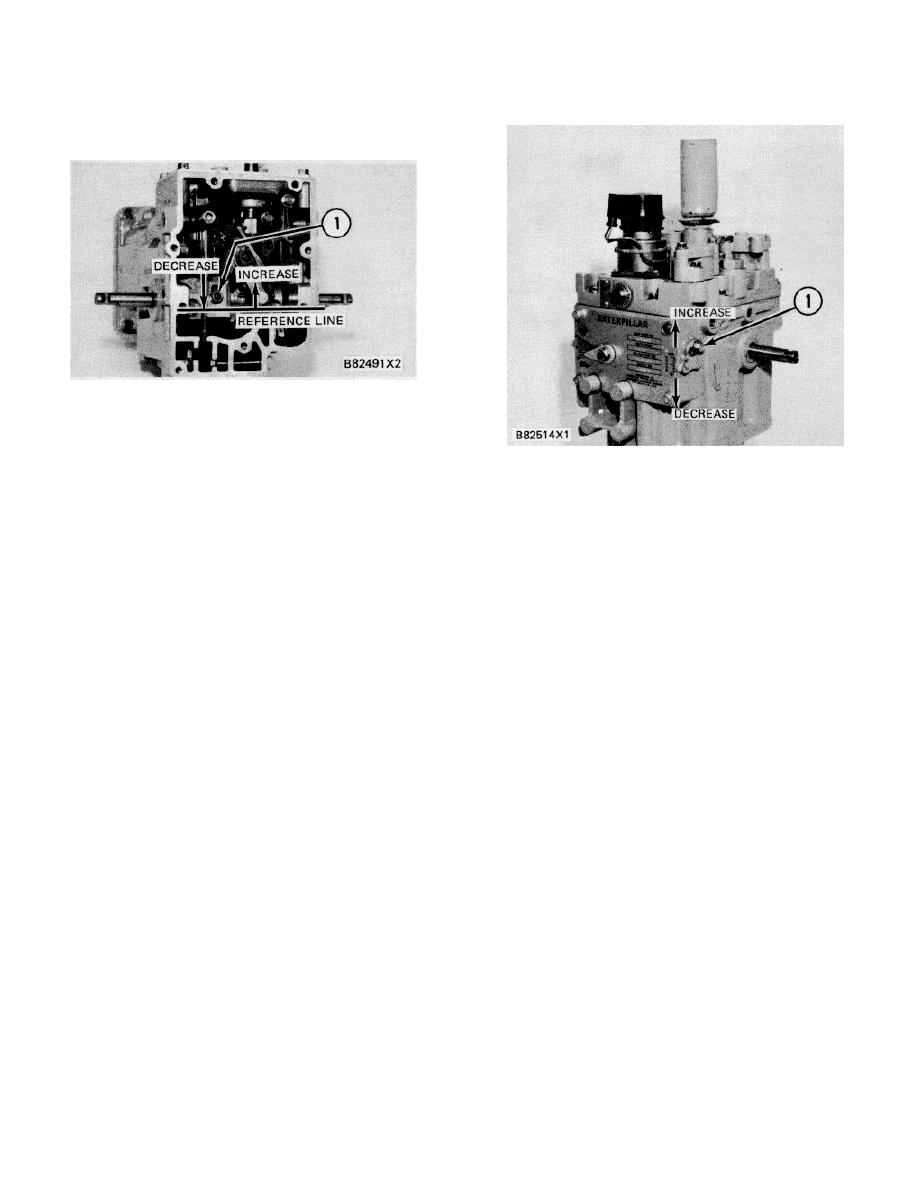

INTERNAL DROOP ADJUSTMENT

1. Locknut.

When the position of the droop pivot pin (internal

EXTERNAL DROOP ADJUSTMENT

or external) is changed on the terminal lever, the percent

1. Bolt.

of governor droop changes.

To change the droop setting, loosen the

To change the droop pivot pin setting on

adjustment lever bolt (1) and move the lever down to

governors not equipped with an external adjustment

decrease droop, and up to increase droop.

lever, the governor top cover must be removed.

DROOP SETTING CHECK

The droop pivot pin is fastened to the terminal

After an adjustment has been made to the droop

lever with locknut (1). With the nut loosened, the pivot

pivot pin (internal or external), the setting can be

pin can be moved from minimum droop to maximum

checked by alternately loading and checking the high idle

droop. It is shown here in the minimum droop position.

speed.

The terminal shafts are clamped in the ends of

As this procedure is performed, the high idle

the terminal lever by two bolts. A line can be drawn

screw will probably have to be adjusted. The full load

through the center of the two bolt heads and used for

speed of the engine will also adjust upward or downward.

reference in adjusting the droop pivot pin position.

As droop is decreased, full load speed is

When the pivot pin and nut is moved near the

increased, high idle speed is decreased. The greater

reference line as shown, the governor is set for minimum

the percent droop, expect the full load speed to

droop. As the pivot pin and nut are moved farther away

decrease, and the high idle speed to increase.

from the reference line, the droop is increased. When

Therefore high idle speed should be adjusted to set the

the pivot pin and nut are moved to the farthest point

full load speed at the correct rpm.

away from the reference line the governor is set for

maximum droop.

COMPENSATION NEEDLE VALVE

ADJUSTMENT

DROOP SETTING - EXTERNAL

ADJUSTMENT

After the engine has started and is under

governor control, open the needle valve (turn it

On the 3161 Generator Set Governor, the

counterclockwise) until governor operation just becomes

internal droop pivot pin locknut must be kept loose

unstable (starts to hunt), then turn the needle valve in

enough to be moved by the external droop adjustment

until engine speed has stability. Let the governor and

lever. The external droop adjustment lever is held in

engine get to operating temperature by operating a

place with a bolt which retains the droop setting.

minimum of one-half hour.

After the engine and

governor are at the operating tempera-

187

|

||

|

||