| Tweet |

Custom Search

|

|

|

||

3500 ENGINES

DISASSEMBLY AND ASSEMBLY

CRANKSHAFT MAIN BEARINGS

follows:

NOTICE

If the crankshaft is turned in the wrong direction, the

tab of the bearing will be pushed between the

crankshaft and cylinder block. This can cause

damage to either or both.

NOTE: On the center main journal that has no oil hole,

put a thin piece of soft material that will not damage the

crankshaft journal against the end of the bearing,

opposite the tab. Hit the bearing with the soft material

until the tab of the bearing is free from the cylinder block.

Remove the upper half of the main bearing.

9.

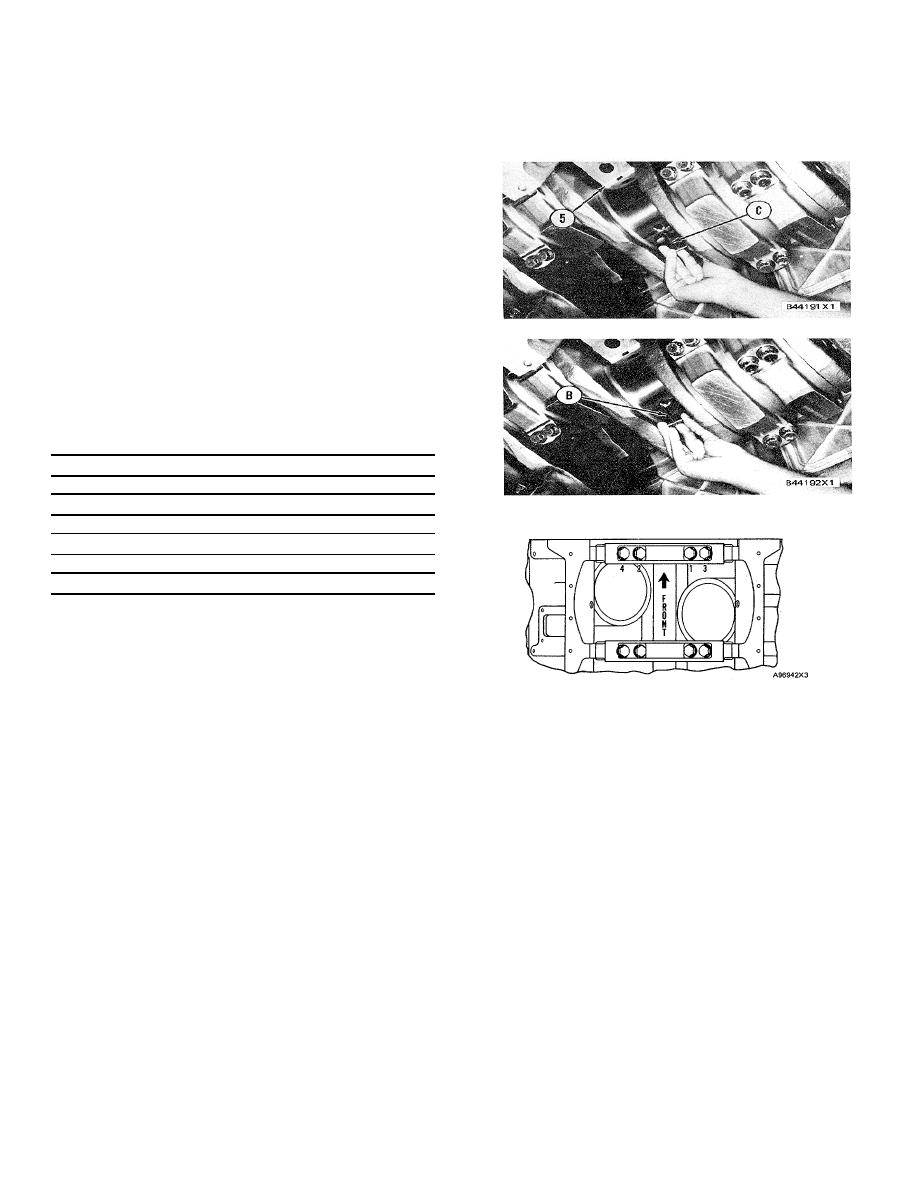

Install tool (C) in the oil hole in the crankshaft

journal and remove upper main bearing halves

(5) as the crankshaft is turned and the bearing is

moved out of the cylinder block.

INSTALL CRANKSHAFT MAIN

BEARINGS

1203-12

Tools Needed

ABCD

9S9082 Engine Turning Pinion 1

2P5517 Bearing Removal and

Installation Tool

1

8S2328Dial Test

Indicator Group

1

6V3147 Main Bearing Wrench

1

NOTICE

Make sure the upper and lower halves of bearings

are installed so the bearing tabs fit into the notch in

cylinder block and bearing caps.

checks are made. Put clean engine oil on the main

a)

Put a piece of the Plastigage on the surface

bearings for final assembly.

of the lower bearing half.

b)

Install the main bearing caps with the word

1.

Install tool (B) in the oil hole of the crankshaft.

"FRONT" and the cast part number toward

Put the upper bearing half (half with oil hole) in

the front of the cylinder block. Each cap

position on the crankshaft. Use tool (A) to turn

has a number on the bottom surface and

the engine flywheel and push the bearing half in

must be installed in the same position as

position with tool (B).

the correct number on the right side of the

2.

Make sure the bearing caps are clean and install

block pan rail.

the lower bearing halves in the caps.

c)

Put clean engine oil on the main bearing

NOTICE

cap bolts and tighten them in the number

Do not use an impact wrench to tighten the

sequence shown with tool (D) to a torque of

bolts the additional 180 5 of a turn more.

136 14 N.m (100 10 Ib.ft.). Then

NOTE: When the bearing clearance is checked and the

tighten the bolts in the number sequence

engine is in a vertical position, such as in the vehicle, the

shown 180 5 of a turn more.

crankshaft will have to be lifted up and held against the

d)

Remove the caps and measure the

upper halves of the main bearings to get a correct

Plastigage. The main bearing clearance

measurement with the Plastigage. The Plastigage will

must be 0.122 to 0.241 mm (.0048 to .0095

not hold the weight of the crankshaft and give a correct

in.).

indication. If the engine is in a horizontal position, it is

not necessary to hold the crankshaft up. Do not turn the

crankshaft when the Plastigage is in position to check

clearances.

3.

Check the bearing clearances with Plastigage as

394

|

||

|

||