| Tweet |

Custom Search

|

|

|

||

3500 ENGINES

DISASSEMBLY AND ASSEMBLY

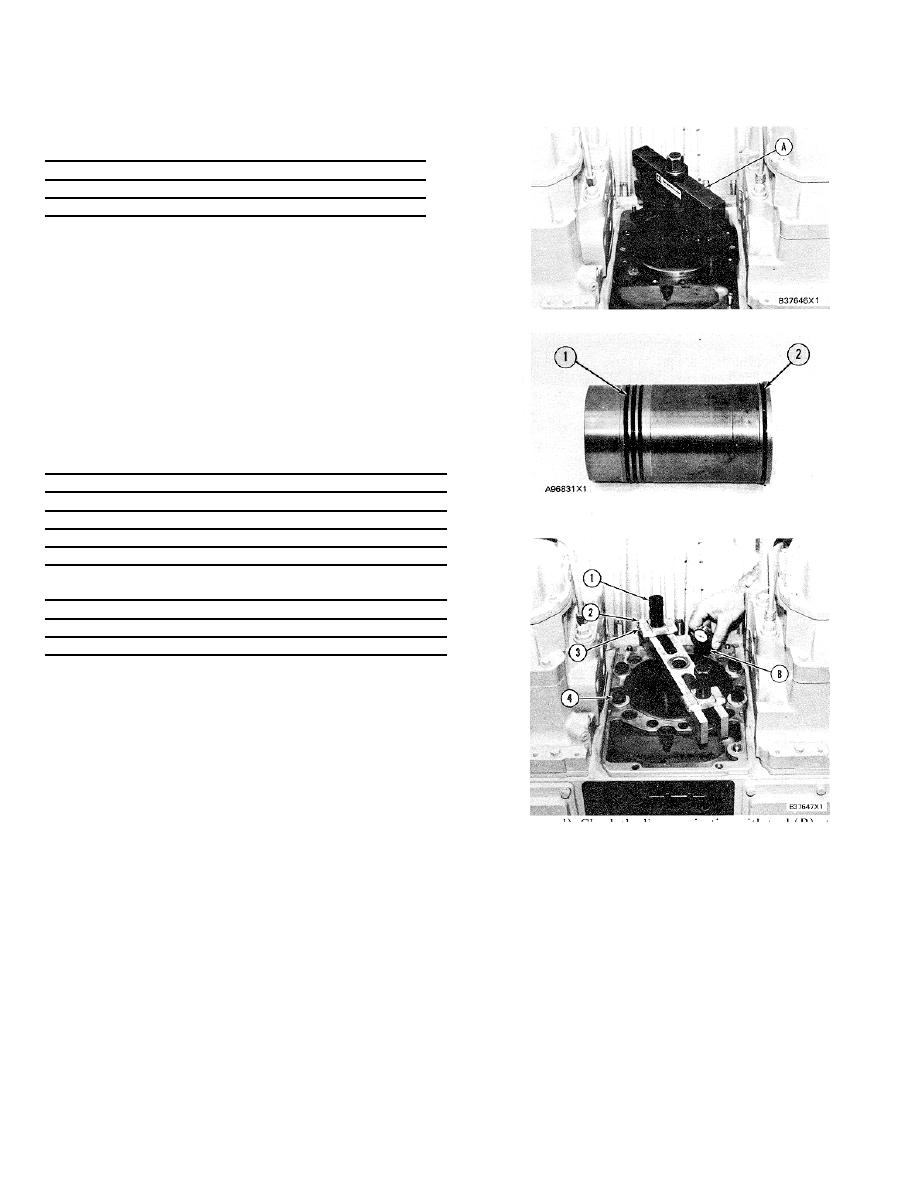

CYLINDER LINERS

REMOVE CYLINDER LINERS

1216-11

Tools Needed

A

5P8665

Cylinder Liner Puller

1

6V4133

Wedge Bracket

1

start by:

a) remove pistons

1.

Drain the coolant from the cooling system and

cylinder block.

2.

Put covers on the crankshaft journals for

protection from dirt and coolant.

3.

Remove the cylinder liner with tool (A).

4.

Remove seals (I) and filler band (2) from the

cylinder liner.

INSTALL CYLINDER LINERS 1216-12

Tools Needed

A

B

C

8B7548 Puller Assembly (Crossbar)

1

3H465

Plate

2

8F6123 Bolt (Y4"-16 NF x 5 /2 in. long)

2

3B1925 Washer (3/4"-Copper)

4

S1575

Bolt (3/4"-16 NF x 3 in. long)

4

1P5510 Liner Projection Tool Group

1

2P8260 Liner Installation Group

1

7N1961 Bolt (from Cylinder head)

1

FT1543 Plate

1

1.

Install the gasket and spacer plate.

2.

Clean the cylinder liners and liner bores in the

cylinder block.

3.

Install the cylinder liners in the cylinder block

without seals or bands.

4. Check the cylinder liner projection as follows:

d) Check the liner projection with tool (B) at

a) Install four bolts (4) and washers from

four locations around the liner.

Liner

tooling (A) around each cylinder liner as

projection must be 0.059 to 0.199 mm

shown. Tighten the bolts evenly to a torque

(.0023 to .0078 in.). The difference between

of 95 N-m (70 lb. ft.).

the four measurements on the same liner

b) Install crossbar (2), plates (3) and bolts (I )

must not be more than 0.05 mm (.002 in.).

from tooling (A). Be sure the crossbar is in

NOTE: If the liner is turned in the cylinder block, it can

position at the center of the liner and the

make a difference in liner projection.

liner surface is clean. Tighten bolts (1)

evenly to a torque of 70 N-m (50 lb. ft.).

c) Check the distance from the bottom edge of

crossbar (2) to the top edge of the spacer

plate. The distance on each end of the

crossbar must be the same.

398

|

||

|

||