| Tweet |

Custom Search

|

|

|

||

3500 ENGINES

DISASSEMBLY AND ASSEMBLY

CRANKSHAFT

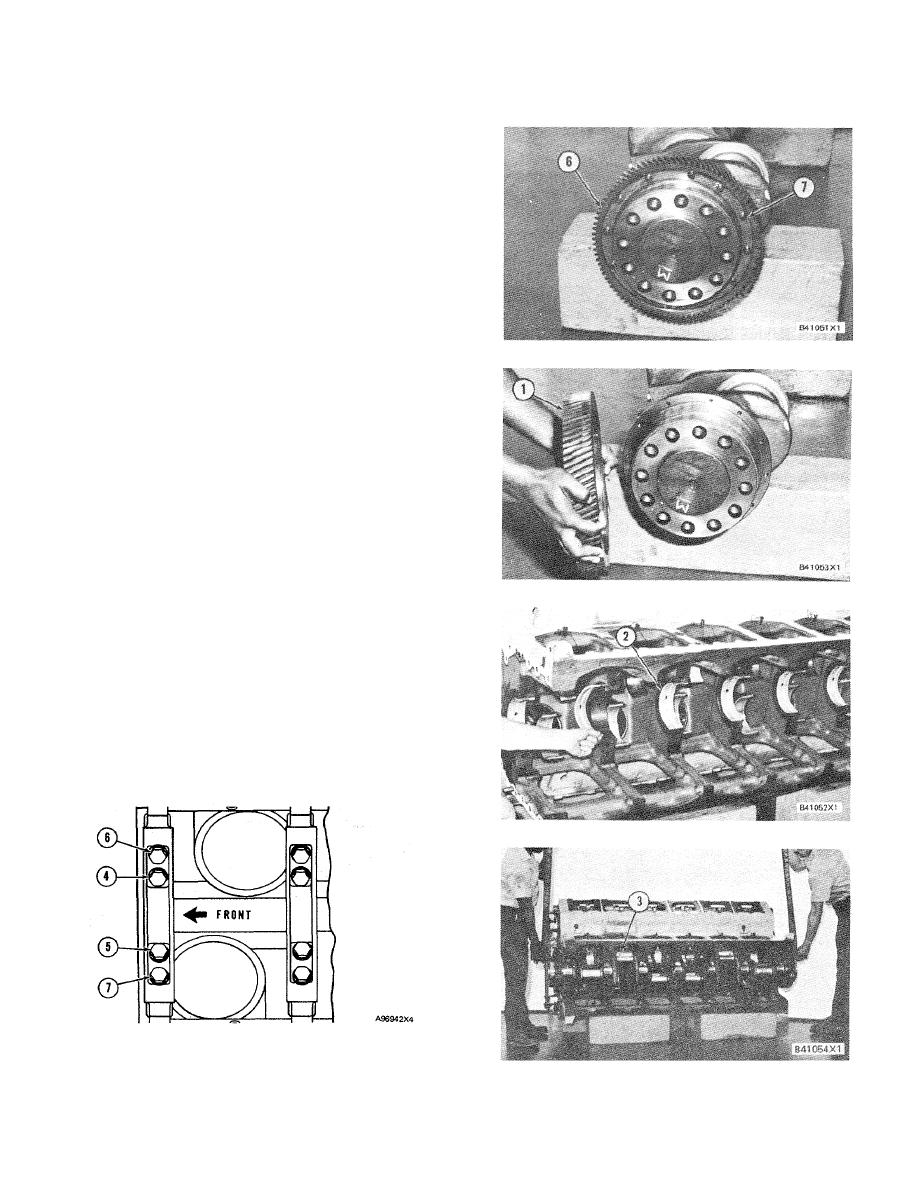

6.

Remove the remainder of main bearing caps (5)

and remove crankshaft (4) from the engine

block. The weight of the 3512 Crankshaft is 454

kg (1000 lb.).

The weight of the 3508

Crankshaft is 299 kg (660 lb.).

7.

If necessary, remove bolts (7) to remove gears

(6) from each end of the crankshaft.

INSTALL CRANKSHAFT1202-12

1.

If gears (I) were removed, install gears (1) on

each end of the crankshaft and install the bolts

to hold the gears.

2.

Make sure the upper halves of main bearings (2)

(bearings with oil holes) are in position in the

cylinder block. Put clean engine oil on the

bearings.

3.

Fasten a hoist to crankshaft (3) with two fly-

wheel bolts and put it in position. Make sure the

word "FRONT" on the end of the crankshaft is

toward the front of the cylinder block.

4.

Make sure the lower halves of the main bearings

are in position in the main bearing caps. Put

clean engine oil on the bearings and install all

but the center main bearing cap on the cylinder

block. The caps must be installed with the word

"FRONT" and the cast part number toward the

front of the cylinder block. Each cap has a

number on the bottom surface and must be

installed in the same position as the correct

number on the right side of the block pan rail.

NOTICE

Do not use an impact wrench to tighten the bolts

1800 + 50 of a turn more.

5.

Put clean engine oil on the main bearing cap

bolts and tighten the bolts in the number

sequence as shown to a torque of 136 + 14 Nm (

100 + 10 lb.ft.). Then tighten each bolt in the

number sequence as shown 1800 + 50 of a turn

more.

408

|

||

|

||