| Tweet |

Custom Search

|

|

|

||

3500 ENGINE ATTACHMENTS

SPECIFICATIONS

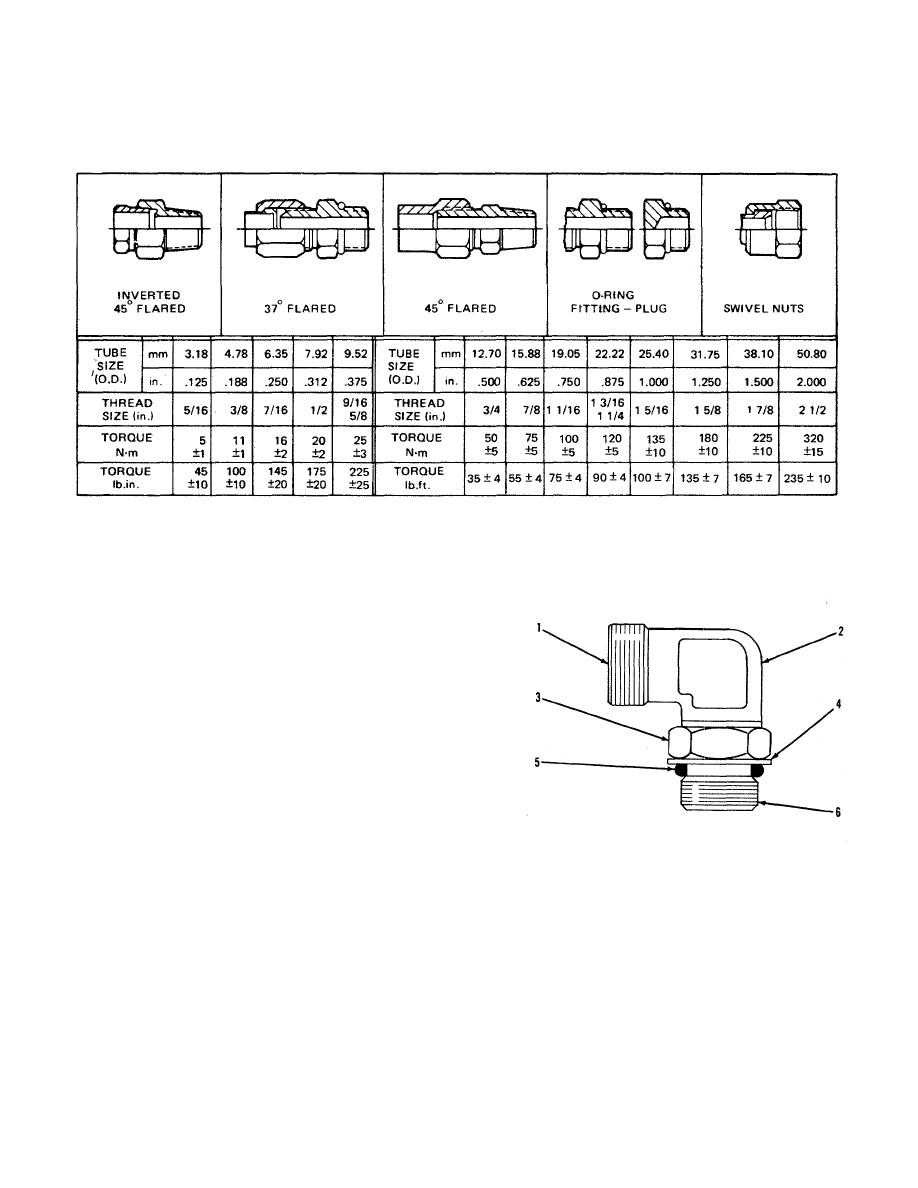

TORQUE FOR FLARED AND O-RING FITTINGS

The torques shown in the chart that follows are to be used on the part of 37 Flared 45 Flared and

Inverted Flared fittings (when used with steel tubing), O-ring plugs and O-ring fittings.

ASSEMBLY OF FITTINGS WITH

STRAIGHT THREADS AND O-RING SEALS

1.

Put locknut (3), backup washer (4) and O-ring

seal (5) as far back on fitting body (2) as

possible. Hold these components in this position.

Turn the fitting into the part it is used on, until

backup washer (4) just makes contact with the

face of the part it is used on.

NOTE: If the fitting is a connector (straight fitting) or plug,

the hex on the body takes the place of the locknut. To

install this type fitting tighten the hex against the face of

the part it goes into.

2.

To put the fitting assembly in its correct position

turn the fitting body (2) out (counterclockwise) a

maximum of 359 Tighten locknut (3) to the

.

torque shown in the chart.

ELBOW BODY ASSEMBLY

A71009X3

1. End of fitting body (connects to tube). 2. Fitting

body. 3. Locknut. 4. Backup washer. 5. O-ring

seal. 6.

End of fitting that goes into other part.

414

|

||

|

||