| Tweet |

Custom Search

|

|

|

||

ELECTRIC PROTECTIVE SYSTEM

TROUBLESHOOTING

PROCEDURE F

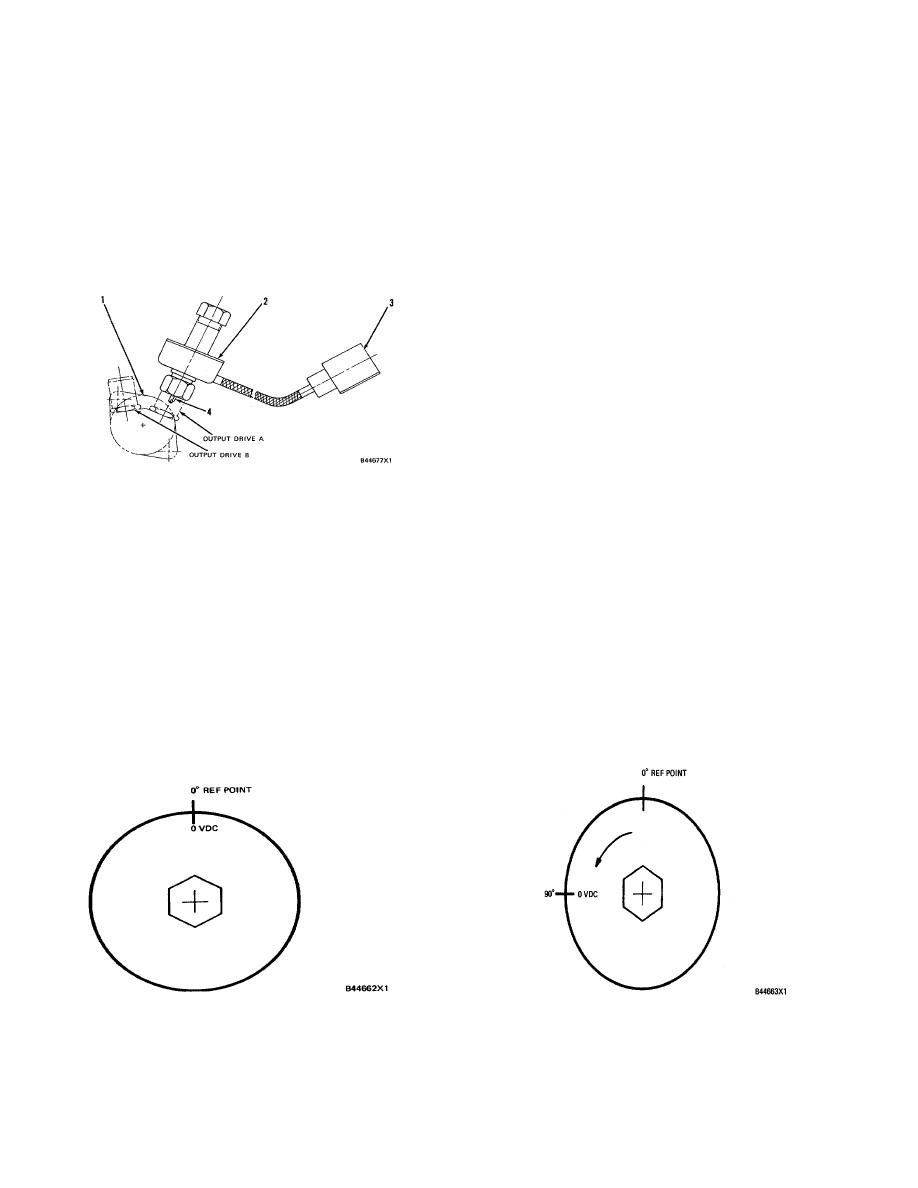

7N7412 SENSOR ASSEMBLY VERIFY

A.

Slowly turn the shaft of 7N7412 Sensor

Assembly

(2)

one

full

turn

in

a

NOTE : For bench testing, connect a voltage source with

a range from 8-40 VDC (24 VDC preferred) across the

counterclockwise direction [as viewed from

electronic speed switch (ESS) terminals ESS-5 and

drive end (4)]. and watch the voltage indication.

ESS-6. Terminal ESS-5 is the battery negative terminal,

A 4 to 6 VDC reading should be seen for all but

and ESS-6 is the battery positive terminal.

one small area of the shaft rotation. Mark the

position of the shaft where the voltage reading

was zero volts. This point is called SW1 00

reference point.

NOTE : If no voltage is indicated between terminal SW1

(ESS-1) and terminal ESS-5 through one full turn of the

sensor shaft rotation, check speed switch for proper

voltages. A voltage of 4 to 6 VDC should be seen across

terminals ESS-4 and ESS-5. If speed switch voltage is

correct, then either the sensor is defective or the wiring

from the sensor to the speed switch is defective.

After finding SW1 0 reference point (the position

INSTALLED SENSOR ASSEMBLY

(Position shown is for RH rear of engine)

where zero voltage was measured on the sensor), an

1. Tachometer drive housing. 2. 7N7412 Sensor

additional zero volts indication will be measured once for

every 900 of shaft rotation from the 0 reference point by

Assembly. 3. Sensor harness connector. 4. Sensor

drive end.

using the sequence that follows:

B.

Connect the positive (+) voltmeter lead to SW2

1.

Disconnect 7N7412 Sensor Assembly (2) from

(ESS-2) and leave the negative (-) voltmeter lead

engine tachometer drive housing (1). Set the

voltmeter (6V3030 Multimeter or a voltmeter of

connected to ESS-5. Now slowly turn the

same accuracy) voltage scale to a scale higher

sensor shaft counterclockwise. A 4 to 6 VDC

than 6 VDC. Connect the voltmeter to the 5N

reading should be seen for all but one small area

1955 Electronic Speed Switch with the positive

of shaft rotation at an interval 900 from the SW1

0

(+) voltmeter lead connected to SW1 (ESS-1)

reference point. Zero volts will be indicated at

and the negative (-) voltmeter lead connected to

this area.

terminal ESS-5 (-).

SW2 CHECK

SW1 CHECK

501

|

||

|

||