| Tweet |

Custom Search

|

|

|

||

ELECTRIC PROTECTIVE SYSTEM

TROUBLESHOOTING

PROCEDURE A

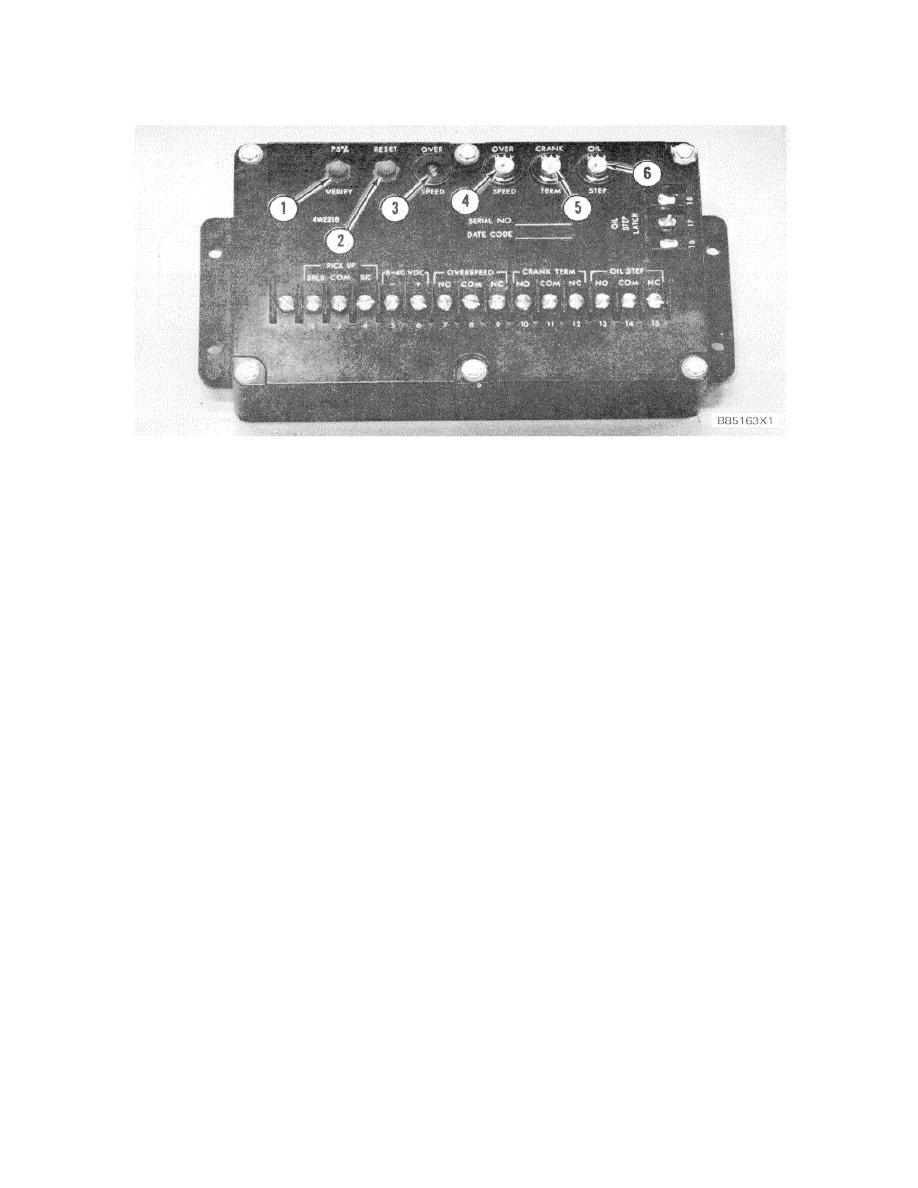

4W2218 ELECTRONIC SPEED SWITCH (ESS)

1. Verify button. 2. Reset button. 3. "LED" overspeed light. 4. Seal screw plug (overspeed).

5. Seal screw plug (crank terminate). 6. Seal screw plug (oil step).

5.

To reset speed switch, push in reset button (2).

OVERSPEED SETTING CALIBRATION

Air inlet shutoff must be manually reset.

1.

Remove lockwire and seal from seal screw plugs

6.

Slowly turn overspeed adjustment potentiometer

(4), (5) and (6). Remove seal screw plug (4)

approximately one turn clockwise and do Steps

from access hole for overspeed adjustment

3, 4 and 5 again.

screw.

NOTE: More adjustment may be needed to get the

2.

Use a small screwdriver and lightly turn

correct setting.

Turn adjustment potentiometer

overspeed adjustment potentiometer twenty

clockwise

to

increase,

speed

setting,

and

turns in the direction of "MAX ARROW"

counterclockwise to decrease speed setting.

Turn

(clockwise).

adjustment potentiometer very slowly only a small

amount at a time until adjustment is correct.

NOTE: The overspeed adjustment screw is made so

that it can not cause damage to the potentiometer, or be

7.

When the speed setting is correct, install seal

removed, if the adjustment screw is turned too many

screw plug (4) in overspeed adjustment access

turns in either direction.

hole. Tighten screw to a torque of 0.20 + 0.03

N-m (2 +.3 lb. in.). Install the lockwire and seal

3.

Run engine at 75% of desired overspeed setting

(if crank termination and oil step adjustments are

rpm.

Make reference to the SPEED

complete).

SPECIFICATION CHART (Part of PROCEDURE

D).

4.

With engine at 75% of overspeed setting rpm,

push VERIFY button (I) and hold in. Turn

overspeed adjustment potentiometer in the

direction

opposite

of

"MAX

ARROW"

counterclockwise) slowly until "LED" overspeed

light (3) comes on. Engine will shutdown if

speed switch is connected to the fuel shutoff

solenoid and/or air inlet shutoff solenoid.

548

|

||

|

||