| Tweet |

Custom Search

|

|

|

||

Maintenance

Recommendations

A 3% to 6% concentration of Caterpillar Cooling System

Never use both the liquid cooling system conditioner and

Conditioner can be maintained by adding .50 liter (1 pint)

coolant conditioner elements at the same time.

for each 15 liters (4 gallons) of coolant used.

Operate with a thermostat in the cooling system all year-

Premix antifreeze solution to provide protection to the

round. Cooling system problems can arise without a

lowest expected ambient temperature. Pure undiluted

thermostat.

antifreeze will freeze at -23C (-10F).

Fuel System

Acceptable water for use in the ethylene glycol-type

antifreeze and water mixture is shown on the chart

NOTICE

below.

Fill the fuel tank at the end of each day of operation

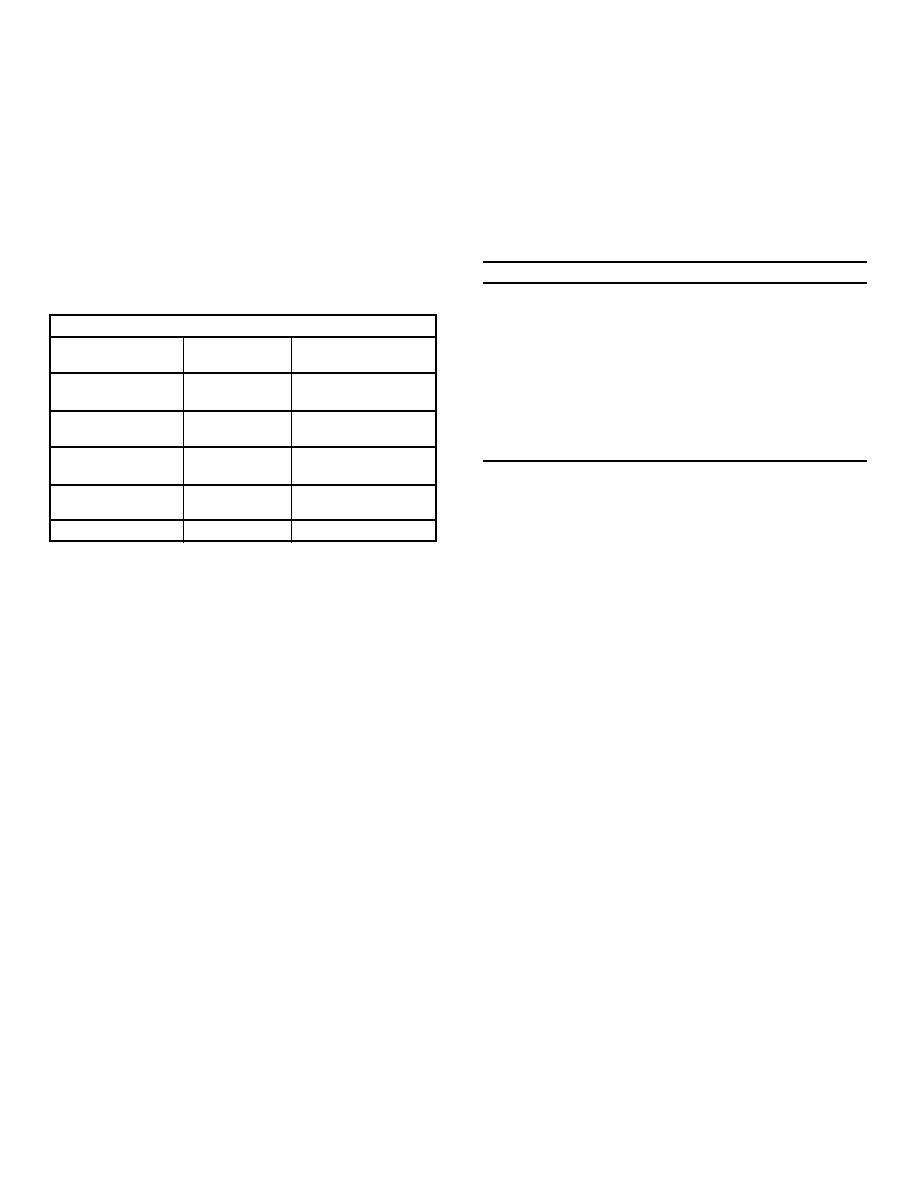

Acceptable Water

to drive out moist air and to prevent condensation.

Do not fill the tank to the top. The fuel expands as it

50% or More

Less Than

gets warm and may overflow.

Water Content

Antifreeze

50% Antifreeze

100 ppm

50 ppm

Do not fill fuel filters with fuel before installing them.

or less

or less

Contaminated fuel will cause accelerated wear to

Sulfates

100 ppm

50 ppm

fuel system parts.

or less

or less

Hardness as

200 ppm

100 ppm

CaCo3

or less

or less

After changing fuel filters, open fuel supply and return

Dissolved Solids

500 ppm

250 ppm

valves that were closed. The fuel system will bleed air

or less

or less

back through the return.

pH

6.5 or higher

6.5 or higher

ppm = parts per million

Drain water and sediment from any fuel storage tank

weekly, and before the tank is refilled. This will help

Use clean water that is low in scale forming mineral. Do

prevent water or sediment from being pumped from the

not use softened water. Add Caterpillar Cooling System

storage tank into the engine fuel tank.

Conditioner, Caterpillar Coolant Conditioner Elements, or

equivalent, to the water to provide corrosion protection.

Use only fuel as recommended in the "Fuel, Coolant and

Lubricant Specifications" section of this guide.

Filling at over 20 liters (5 U.S. gallons) per minute can

cause air pockets in the cooling system.

Air Intake System

After draining and refilling the cooling system, run the

As the air cleaner elements become plugged, the

engine with the filler cap off until the coolant reaches

difference of air pressure between the inlet side (dirty

normal operating temperature and the coolant level

side) and the engine side (clean side) will increase.

stabilizes. Add coolant as necessary to fill the system to

Service the air cleaners when the air cleaner restriction

the proper level.

gauge registers 762 mm (30 inches) H20.

588

|

||

|

||