TM 5-2815-241-34&P

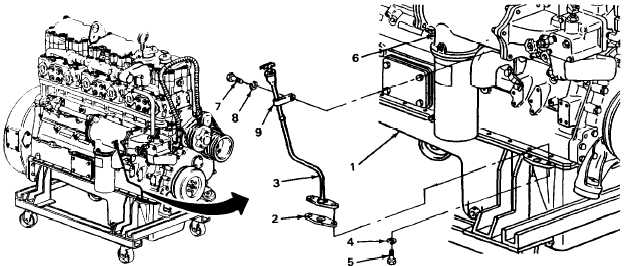

OIL DIPSTICK TUBE INSTALLATION

INITIAL SETUP

Tools

Materials/Parts

Socket, 9/16-inch, 12-inch drive

Socket, 5/8-inch, 1/2-inch drive

Wrench, torque, 0 to 150 ft lb

(0 to 210 N•m), 1/2-inch drive

Gasket

Lockwasher, bracket

Lockwasher, oil dipstick tube (two required)

ACTION

LOCATION

ITEM

REMARKS

NOTE

Remove screw from oil cooler before installation of oil dipstick tube.

1. Oil pan (1)

New gasket (2) oil

dipstick tube (3), two

new lockwashers (4),

and two screws (5)

a.

b.

2. Oil cooler (6)

Screw (7), new

lockwasher (8)

and bracket (9)

a.

b.

Position gasket and oil dipstick tube on

oil pan and put in two screws with new

lockwashers and tighten until snug.

Using 1/2-inch drive 5/8-inch socket

and 0 to 150 ft lb (0 to 210 N•m) torque

wrench, torque to 30 to 35 ft lb (40 to

47 N•m).

Screw in.

Using 1/2-inch drive 9/16-inch socket

and 0 to 150 ft lb (0 to 210 N•m) torque

wrench, torque to 30 to 35 ft lb (40 to

47 N•m).

TASK ENDS HERE

TA 242422

2-133

|

|