TM 5-2815-241-34&P

FUEL PUMP - CONTINUED

ACTION

LOCATION

ITEM

REMARKS

d.

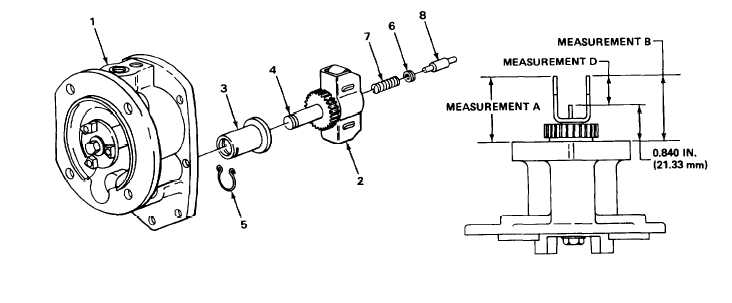

Add measurements A and B and divide

by 2.

Record finding C.

e.

Using 0 to 1-inch depth micrometer,

center depth micrometer on weight

carrier over weight assist plunger and

measure distance to end of weight assist

plunger.

Do not depress weight assist spring.

Record measurement D.

f.

Subtract measurement D from finding C.

The result is the weight assist protru-

sion. Weight assist protrusion should

be 0.840 inch (21.33 mm). If weight

assist protrusion is below 0.840 inch

(21.33 mm), add weight assist shims

(5). If weight assist protrusion is above

0.840 inch (21.33 mm), remove

shims (5), or if no shims are used,

grind small end of weight assist plunger.

Weight assist shims are available in

0.007 inch (0.178 mm) and 0.016 inch

(0.406 mm) thicknesses.

TA 242551

2-321

|

|