*C2

C H A P 5, SEC V

F L A N G E A D A P T E R R E B U I LD

PAR 8 6 - 91

(4) Install thrust washer 100 and front-

washer assembly 81. Install retaining ring 80.

( 5 ) I n s t a l l t h r u s t w a s h e r 1 0 3 i n t o t he

s t a t o r a s s e m b l y.

(6) Install thrust bearing assembly 102

o n t o f r e e w h e e l r a c e 1 0 1 , u s i n g o i l - s o l u b l e

grease to retain it.

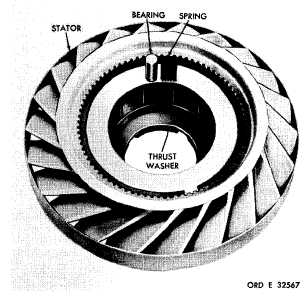

(7) Using a heavy oil-soluble grease to

r e t a i n t h e m , p o s i t i o n t h e 1 2 b e a r i n g s a n d

springs in the 12 stator cam pockets. Fig. 148

shows the location of the bearings and springs

i n r e s p e c t t o t h e s t a t o r a s s e m b l y . I n s t a l l a

spring into the deep end of the cam pocket.

Place a bearing in the shallow end of the cam

p o c k e t b e s i d e t h e s p r i n g . I n s t a l l r e m a i n i ng

11 bearings and springs in the same manner.

(8) Install freewheel race 101 (fig. 373,

fold-out 2) with bearing 102 into the stator as-

s e m b l y .

Figure 148. Torque converter stator

S e c t i o n V . F L A N G E A D A P T E R A S S E M B L Y — R E B U I LD

8 7 . D E S C R I P T I O N

R e f e r t o p a r . 8 f o r t h e d e s c r i p t i o n o f t h e

f l a n g e a d a p t e r a s s e m b l y .

8 9 . C L E A N I NG

Refer to par. 71 for cleaning recommend-

a t i o n s .

9 0 . I N S P E C T I O N A N D R E P A IR

R e f e r t o p a r . 7 2 f o r g e n e r a l i n s p e c t i on

and repair recommendations. Repair and re-

b u i l d p o i n t s o f m e a s u r e m e n t f o r f i t s , c l e a r-

ances and wear limits are indicated by small

letters in fig. 373, fold-out 2. Refer to par.

236 for wear limits information.

1

0

8

9 1 . A S S E M B L Y

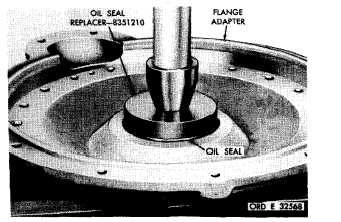

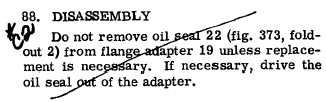

a . If the oil seal was removed from the

flange adapter, install a new replacement using

oil seal replacer 8351210 (fig. 149).

b . Install oil seal, lip side down, press-

i n g t h e s e a l u n t i l i t i s s e a t e d a g a i n s t i t s

shoulder in the adapter (fig. 149).

Figure 149. Installing oil seal in flange adapter

|

|