P A R 2 2 7 , S T E P S 6 3 - 6 6

A S S E M B LY

C H A P 5, SEC X X X I II

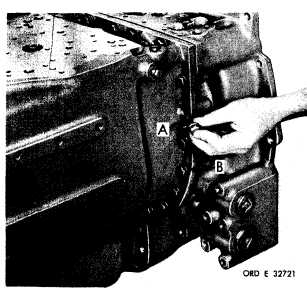

Figure 302 (Step 63)

I n s t a l l t h i r t y - t h r e e 7 / 1 6 - 1 4 x 1 - 1 / 2 b o l t s

( A ) a n d l o c k w a s h e r s ( B ) . U s i n g a 5 / 8 - i n ch

wrench, torque bolts to 42-50 pound-feet.

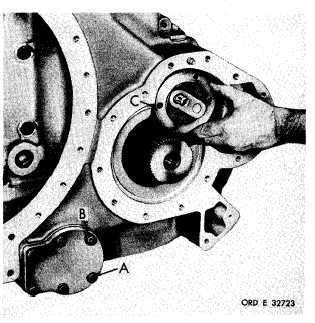

Figure 303 (Step 64)

Using a 5/8-inch wrench, tighten five 7/16-14

x 4 self-locking bolts (A) to 54-65 pound-feet

torque. Install oil screen (B), gasket (C) and

cover (D).

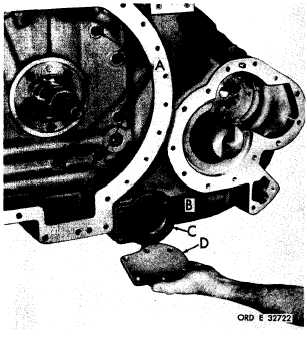

Figure 304 (Step 65)

I n s t a l l s i x 3 / 8 - 1 6 x 1 - 1 / 8 b o l t s ( A ) a n d l o ck

w a s h e r s ( B ) . U s i n g a 9 / 1 6 - i n c h w r e n c h,

torque bolts to 26-32 pound-feet. Install out-

put oil pump assembly (C).

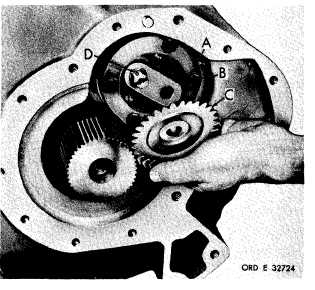

Figure 305 (Step 66)

Secure output oil pump assembly (A) with four

3/8-16

x

2

self-locking

bolts

(B).

Using

a

9 / 1 6 - i n c h w r e n c h , t o r q u e t h e b o l t s t o 3 6 - 43

p o u n d - f e e t . I n s t a l l o i l p u m p d r i v e n g e a r ( C)

and key (D).

1 7 9

|

|