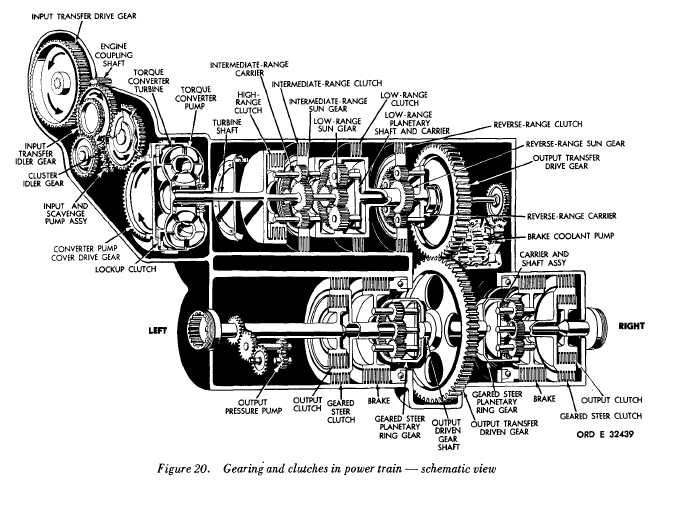

Figure 20

P A R 4 3 - 4 4

T O R Q U E P A T H S

C H A P 2, SEC V

mitted hydraulically from the converter pump

t o t h e c o n v e r t e r t u r b i n e . W h e n t h e l o c k up

clutch is engaged, the pump and turbine are

locked together and torque is transmitted me-

c h a n i c a l l y .

b . W h e n t r a n s m i t t e d h y d r a u l i c a l l y , t he

torque maybe multiplied as much as 3.3 times

(at turbine stall). When transmitted mechani-

cally, torque leaving the converter is equal to

t h a t e n t e r i n g i t . T h e l o c k u p c l u t c h e n g a g es

and releases automatically.

c . At lower speeds, when high torque is

r e q u i r e d , t h e l o c k u p c l u t c h i s r e l e a s e d . At

higher speeds, when less torque is required,

the lockup clutch is engaged. Lockup engage-

m e n t c a n o c c u r i n e v e r y g e a r r a n g e a n d in

neutral. In figures 22 through 34 the converter

output is indicated by yellow when the lockup

clutch is released; by red when engaged.

4 4 . T O R Q U E P A T H - O U T P UT

TRANSFER GEARING (fig. 20)

a . Two gears makeup the output transfer

gearing. The drive gear is splined to the low-

range carrier shaft which is the range gearing

output for the power train regardless of which

gear is engaged.

The drive gear meshes with

the driven gear and imparts opposite rotation.

b . T h e d r i v e n g e a r t r a n s m i t s t o r q u e,

through a splined shaft, to the steer planetary

ring gears on either side of the driven gear.

The speed reduction, and corresponding torque

i n c r e a s e , i s 1 . 3 0 t o 1 . 0 0 .

4

7

|

|