TM 9-2520-272-34&P

4-6. INSTALL TRANSMISSION ON MAINTENANCE STAND

10

11

12

13

14

15

16

17

18

(SHEET 6 OF 7)

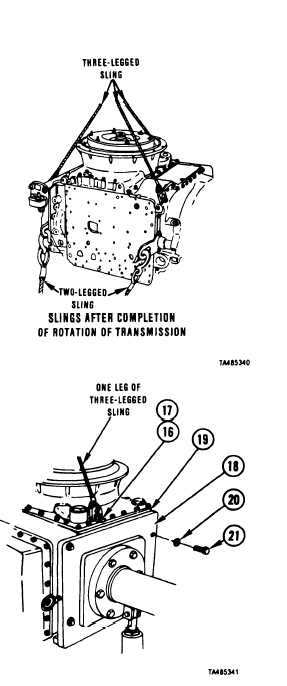

WARNING

When rotating transmission vertical to

horizontal position, weight of transmission

is transferred from one Sling to the other.

When the center of gravity shifts,

transmission may suddenly tilt, thrusting

heavy momentary stress on sling and hoist.

To avoid injury or death, keep out from

under and clear of transmission at all times.

Raise two-legged sling as necessary to maintain proper

clearance between transmission and floor

Slowly raise three-legged sling until weight of

transmission is entirely on three-legged sling.

Remove two-legged sling.

Rotate adapter plate (18) on maintenance stand to

match hole pattern in plate with holes on bottom of

transmission (19).

Using aligning punch hoist, and rotational control on

maintenance stand, align holes in bottom of

transmission (19) with holes in adapter plate (18).

Install washers (20) under heads of three 1/2-32 x 2

inch bolts (21). Using 3/4 inch socket, install bolts

through three holes in adapter plate (18). Screw bolts

into holes on bottom of transmission (19).

Using torque wrench, tighten bolts (21) to 80-95 lb-ft

(108-129 N•m).

Using 9/16 socket, remove three 3/8-16 x 1-3/4 inch

bolts (16) and six washers (17) holding three-legged

sling.

Remove three-legged sling.

Go to Sheet 7

4-18

Para. 4-6, Task 2

|

|