| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

FUEL INJECTION NOZZLE REPLACE/REPAIR

0114 00

TEST (Continued)

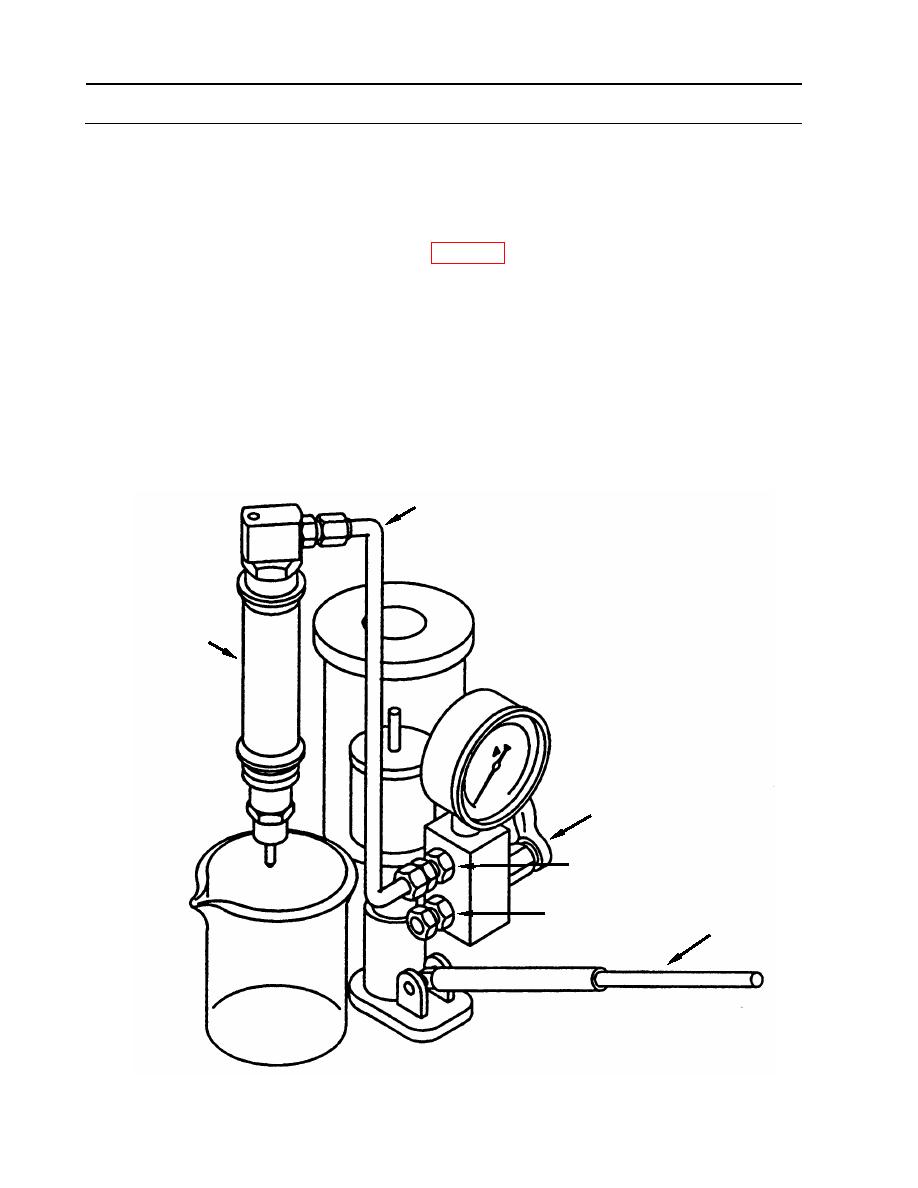

8. Check nozzle seat leakage.

a. Disconnect metal tube assembly (14) from lower connector (15) and move to upper

connector (20).

b. Dry the nozzle tip with a cloth (item 10, WP 0173).

c. Open pressure gauge valve (17) and actuate tester slowly to build up pressure to 300 psi

(20685 kPa) below the valve opening pressure and hold for 5 seconds.

d. If drops of fuel form at spray orifices, or if fuel issues as a stream at 300 psi (2068.5 kPa)

below the valve opening pressure (3550 psi), close the pressure gauge valve (17) and

actuate the pump handle (18) rapidly eight to ten times. Repeat steps 8b and 8c. If drops

form or fuel issues as a stream, the nozzle and holder assembly (3) is leaking and must be

repaired. Go to Disassembly and Repair in this work package.

9. After successful testing, remove the nozzle assembly from test stand and install protective caps

and plugs.

14

3

17

20

15

18

WP 0114 00-6

|

||

|

||