| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-1

(2) Install rod cap and torque to specifications in table 3-3.

(3) Place rod in checking fixture and check length. If rod length is 11.991 in. (304.571 mm) or less, rod cannot

be resized and must be discarded.

NOTE

Maximum of 0.009 in. (0.228 mm) may be machined from cap and rod. Equal stock

must be removed from cap and rod. Rod must measure 12.000 in. (304.800 mm) in

length to remove 0.009 in. (0.228 mm) from mating surfaces. Center-to-center

length must be 11.991 in. (304.571 mm) after grinding and lapping.

(4) Remove rod from checking fixture and remove cap.

WARNING

WEAR PROTECTIVE CLOTHING AND GOGGLES WHILE GRINDING TO PREVENT

PERSONAL INJURY FROM FLYING PARTICLES.

(5) Mount rod in grinding machine and remove material as required.

(6) Mount cap in grinding machine and remove material as required.

(7) Lap rod and cap mating surfaces.

(8) After lapping, apply Prussian bluing to machined surfaces.

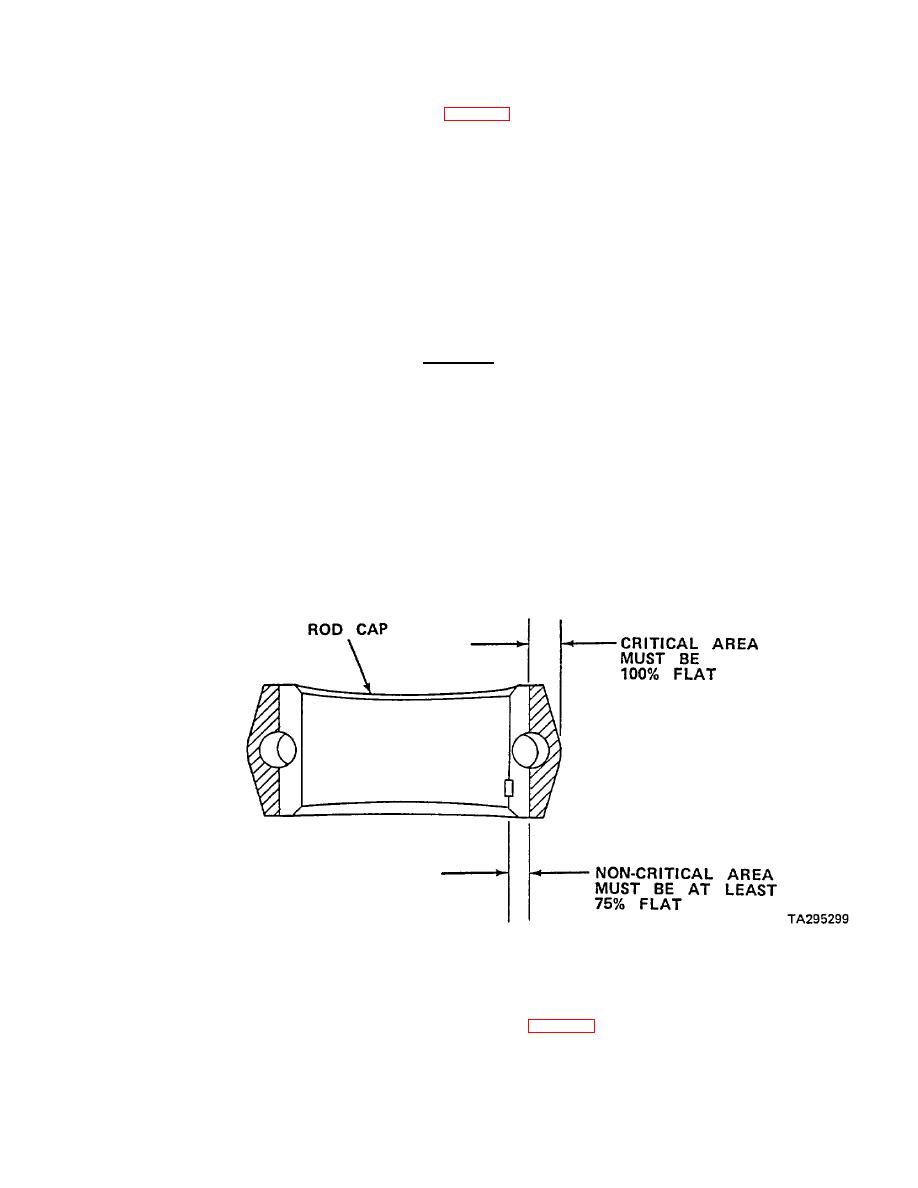

(9) Seating and flatness pattern must show minimum of 75 percent contact with surface plate.

NOTE:

FLATNESS

PERCENTAGE

AND

LOCATIONS

ALSO

APPLY TO CAP MATING

FLANGE ON ROD.

(10) Non-contact area must not be in critical area outside bolt centerline (area furthest from bore centerline).

That area must indicate 100 percent contact.

(11) Secure rod cap to rod and torque bolts to specifications in table 3-3.

3-135

|

||

|

||