| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-1

e. The ring groove width can also be checked by the following method:

(1)

Check ring groove wear using a segment of a new ring and feeler gage.

(2)

Hold ring in groove, flush with ring land.

(3)

Try to insert 0.006 in. (0.152 mm) feeler gage between ring and groove land.

(4)

If gage enters groo ve without forcing or disengaging ring, wear is excessive and piston must be discarded.

NOTE

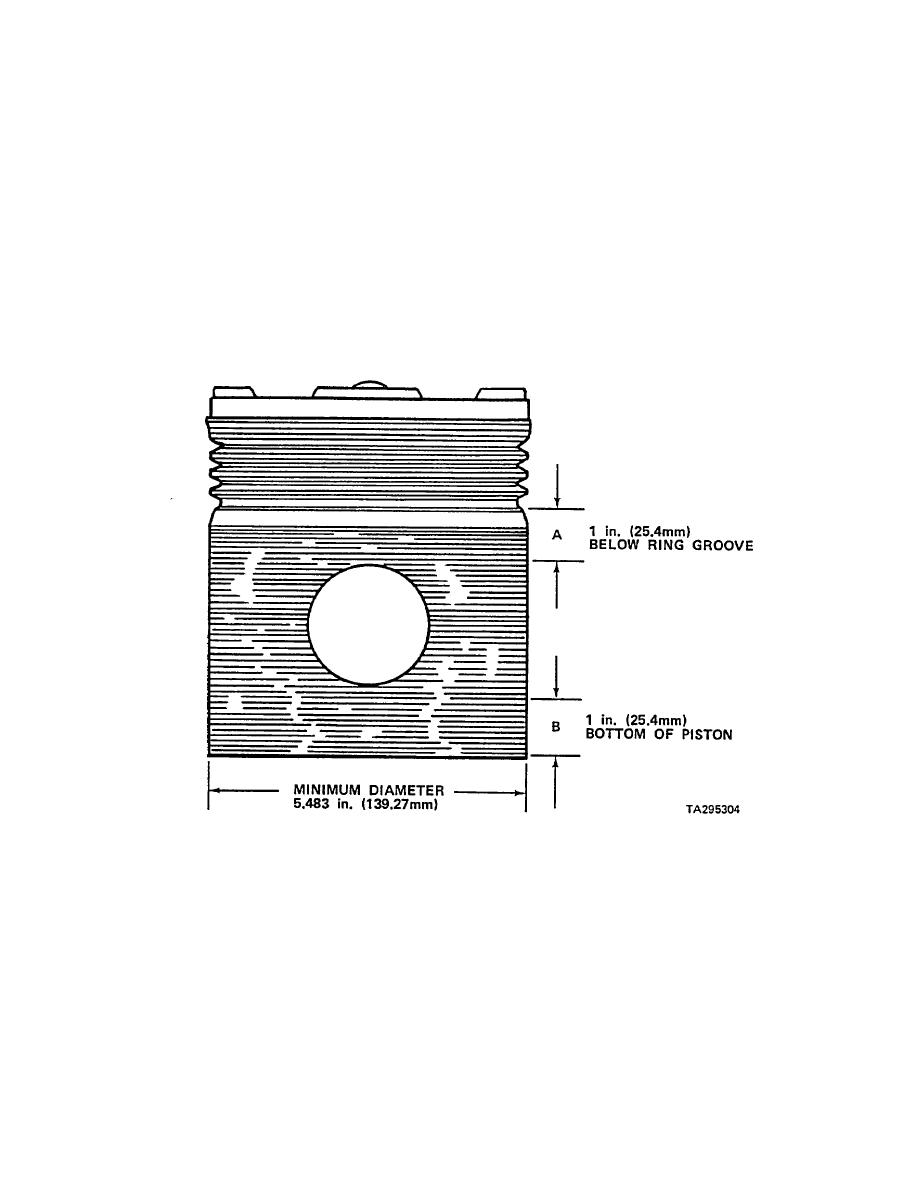

Piston diameter should be checked at temperature of 70F - 90 F (211C - 32C).

Piston to cylinder liner clearance may be determined after measuring piston and

comparing with liner inside diameter.

f. Check measurement of piston skirt diameter using a micrometer at right angle to piston pin bore. A and B of

above illustration points out measurements.

3-143

|

||

|

||