| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-1

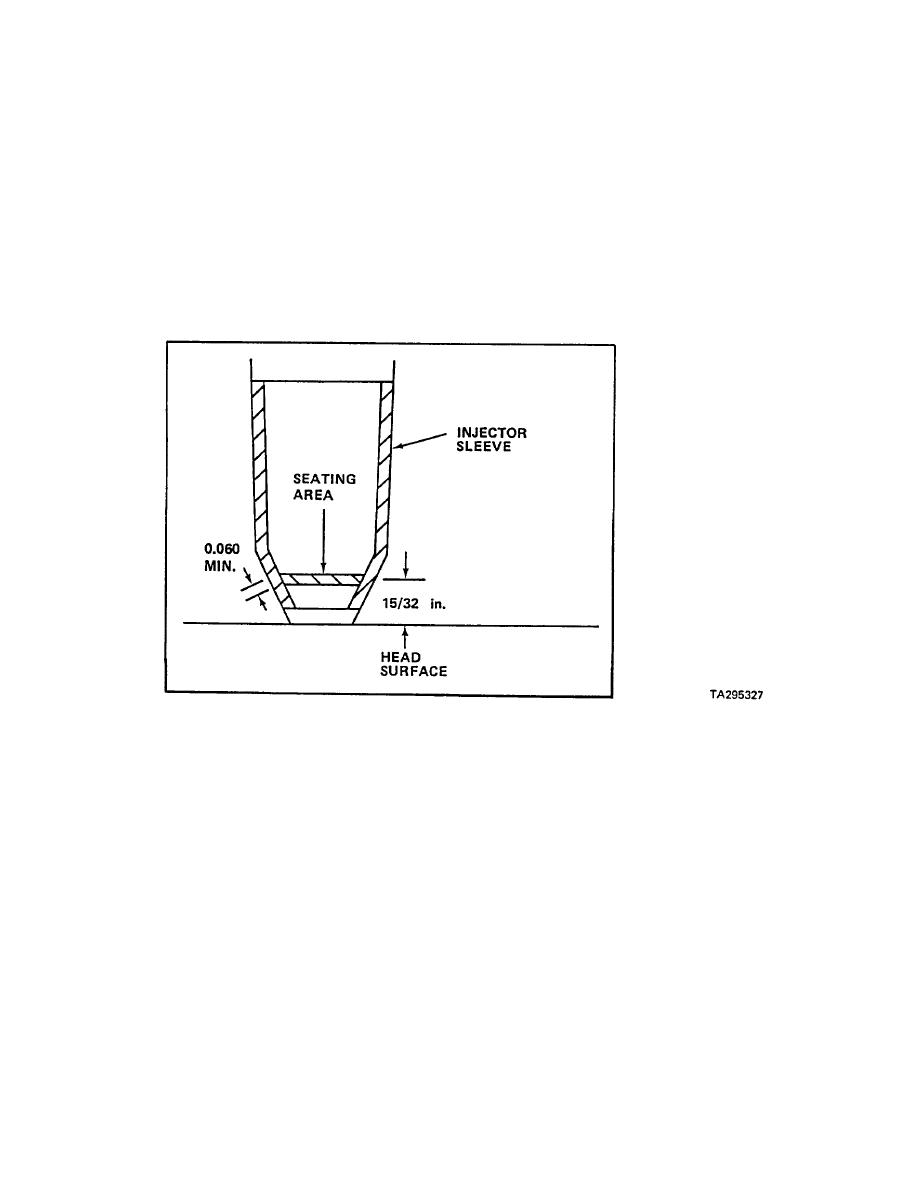

f. Injector sleeve seating area pattern and tip protrusion inspections.

NOTE

Injector sleeves that have passed both air pressure test and seat area scratch

inspection are further inspected for seating pattern and tip protrusion.

(1) Lightly coat new injector cup (on injector body) with Prussian bluing.

(2) Install injector in sleeve. Torque capscrews to 10 - 12 ft lbs (14 - 16 Nm).

(3) Remove injector and check seat pattern. Bluing band must be 0.060 in. (1.52 mm) minimum in width and

located approximately 15/32 in. (11.91 mm) from bottom of head surface.

(4) Mark sleeve for replacement if seat area does not meet specifications.

(5) Reinstall injector and capscrews. Torque capcrews to 10 - 12 ft lbs (14 - 16 Nm).

3-164

|

||

|

||