| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-2

(10) Using ST-1184 clamps and tool no. 3376220 gage block, recheck liner protrusion.

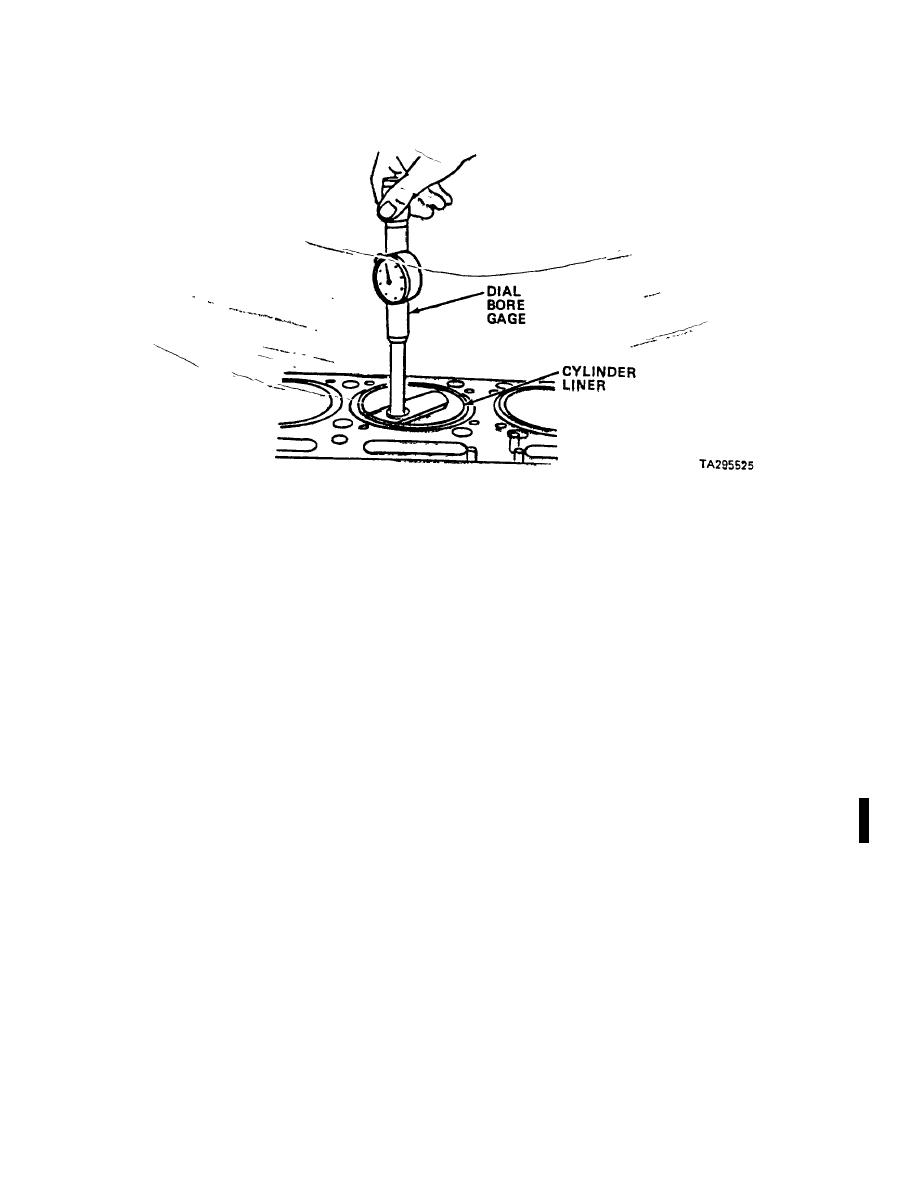

(11) With dial bore gage, measure inside diameter at several points of liner within range of piston travel to

determine if out-of-round.

(12) If liner is more than 0.002 in. (0.050 mm) out-of-round in crevice seal/ O-ring area, remove liner and check

for causes of distortion.

(13) If liner is more than 0.003 in. (0.076 mm) out-of-round at top one inch (25.4 mm) of liner, remove liner and

check for causes of distortion.

d. Install crankshaft and main-bearings.

(1) Turn cylinder block upside down.

(2) Wipe main bearing bores, caps, and bearing halves clean.

NOTE

Main bearing caps on 1980 and 1982 models have 1 in. diameter bolts with a

lockplate; 1984 models have 3/4 in. bolts with washers. (Refer to paragraph 3-

6.m for torque requirements.)

Upper main bearing halve s are grooved and drilled to provide oil flow into

halves. Bearing halves numbers 1, 3, and 5 are alike and numbers 2, 4, and 6

are alike. Number 7 has oil groove and hole off-center. That bearing is

installed with its wide portion toward flywheel end of block.

(3) Thoroughly coat upper main bearing halves with engine oil.

Change 1 3-401

|

||

|

||