| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-2

(j)

Bump housing in direction necessary to bring run-out within specification.

(k)

With housing correctly positioned, progressively torque capscrews alternately from side

to side and top.

(l)

Apply torque in increments of 50 ft lbs (68 N m) until final torque of 150 ft lbs (203 N m)

is reached.

(m)

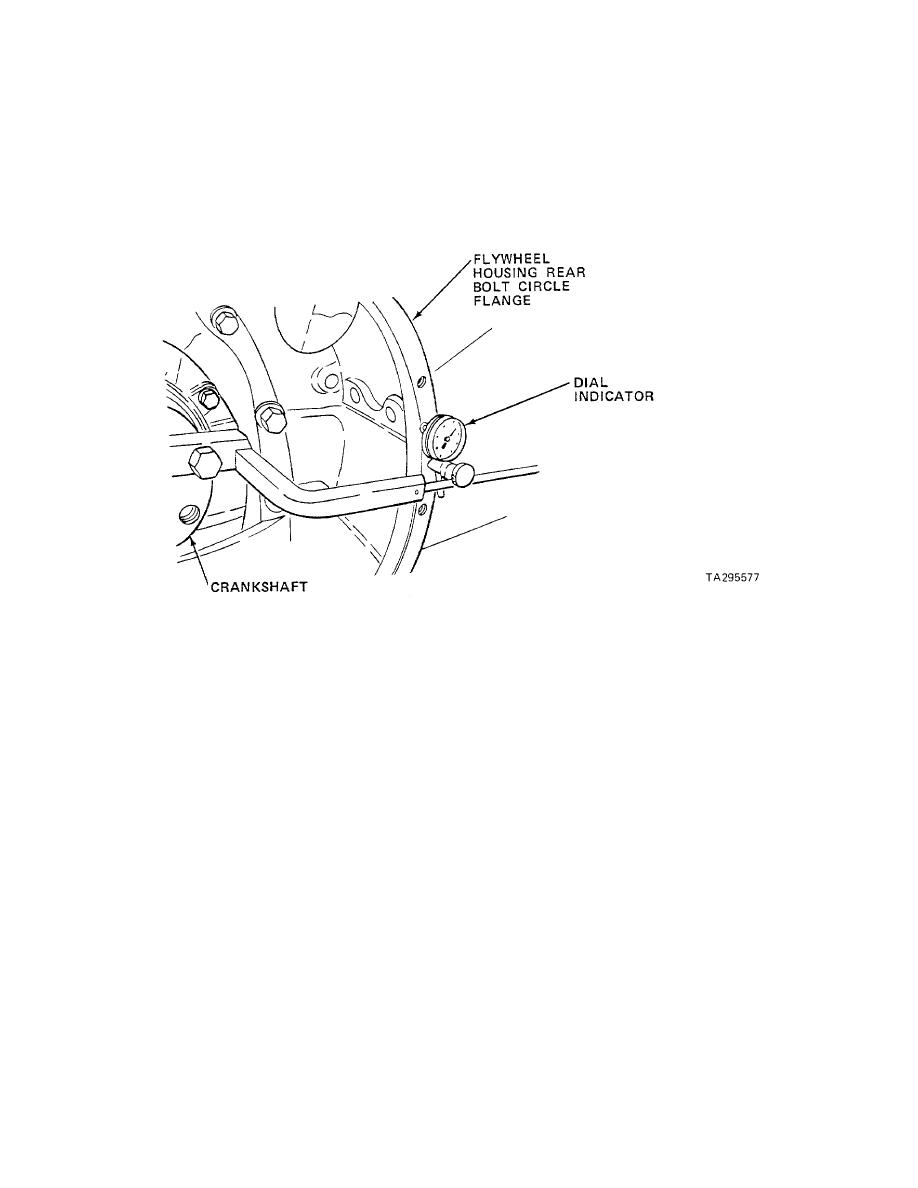

Reposition dial indicator so that its contact pin rides against rear bolt circle flange of

housing.

(n)

Push crankshaft full forward to take up end clearance.

(o)

With crankshaft kept forward, rotate shaft one full turn while observing indicator reading.

(p)

If total indicated run-out exceeds 0.006 in. (0.152 mm), remove housing and inspect

cylinder block and housing mating surfaces.

(q)

Remove any nicks or burrs with fine file and emery cloth. Ensure that surfaces are clean.

(r)

Reinstall housing and reestablish concentricity.

(s)

Remeasure rear flange run-out.

(t)

If run-out is still not correct and crankshaft was kept full forward when rotated, replace

housing.

(u)

If both concentricity and rear flange run-out are within limits with dowel pin removed,

dowel holes in housing and bores in cylinder block must be reamed to accept oversize

pins.

3-447

|

||

|

||