|

|

|

|

|

TM 9-2815-237-34

2-32. FUEL INJECTION PUMP REPAIR [Cont’d)

14.

15.

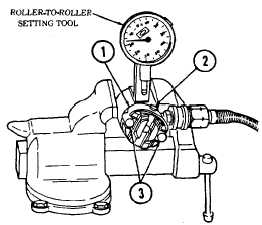

Install roller-to-roller setting tool in soft-jaw vise.

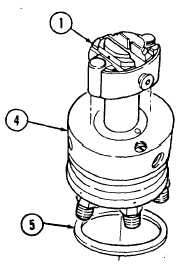

Install roller (1) in roller-broiler setting tool.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

WARNING

Always wear eyeshields when using compressed air. Failure to

wear eyeshields may result in eye injury.

Apply compressed air regulated to 40-100 psi (276-689 kPa) to roller-broiler setting tool.

NOTE

Increase roller-to-roller dimension 0.006 in. (0.152 mm) if using

oversize cam ring.

Measure roller-to-roller dimension and compare to pump specification 1.981 in. (50.31 mm).

NOTE

Roller-to-roller dimension is a completely accurate maximum fuel

adjustment and should not differ from pump specification.

Turn leaf spring adjusting screw (2) clockwise to increase or counterclockwise to decrease roller-

to-roller dimension.

Rotate rotor (1) until one cam roller (3) aligns with roller-to-roller setting tool dial indicator plunger.

Loosen indicator dial retaining screw and set preload by sliding indicator down until plunger

depresses on cam roller (3) 0.015 in. (0.381 mm). Tighten screw.

Rotate dial on indicator to “zero” indicator on high point of cam roller (3).

NOTE

If cam roller centrality is greater than 0.008 in. (0.203 mm),

cam shoes can be interchanged or replaced to achieve tolerance.

Centrality must be rechecked after each time components are

changed.

Measure cam roller centrality by rotating rotor (1) in either direction until high point of other

cam roller (3) depressed dial indicator plunger. Indicator reading should be 0.000 in. to 0.008 in.

(0.000 to 0.203 mm).

Rinse hydraulic head (4) with calibrating fluid.

Remove rotor (1) from roller-to-roller setting tool and rinse with calibrating fluid.

Install rotor (1) in hydraulic head (4).

2-110

|

|

|

|

|

Privacy Statement -

Copyright Information. -

Contact Us