TM 9-2815-237-34

Change 1 2-140.3

2-35.1. (6.5L) FUEL INJECTION PUMP (DB2831-5209) CALIBRATION (Cont’d)

d. Injection Pump Settings (Following Pump Repair)

(b)

Energize electric shutoff solenoid and check delivery against the chart below.

1.

Roller-to-roller dimension must be 1.964 ± .001 in. (49.89 ± .025 mm). With oversize cam ring

installed, roller-to-roller dimension will be 1.972 ± .001 in. (50.09 ± .026 mm). Maximum eccentricity

allowed is 0.008 in. (0.20 mm) TIR.

2.

Linkage gap must be 0.130-0.1734 in. (3.30-4.40 mm).

(a)

Mount the pump horizontally in holding fixture and remove governor cover.

(b)

Hold the throttle lever in the WOT position. Rotate pump driveshaft counterclockwise until a

click is heard as the rounded contact points on the governor arm engage the slots in the thrust

sleeve. Continue to rotate driveshaft until gap between governor arm and pump housing is

minimal.

(c)

Using linkage gap tool, check clearance limits between rear of shutoff shaft and vertical tab on

linkage hook.

(d)

If adjustment is required, loosen governor linkage hook adjustment screw and extend linkage

hook to its maximum open length (throttle lever must be in WOT).

(e)

Insert appropriate step of linkage gap tool between vertical hook tab and throttle shaft, with

step facing shaft. The tool must be held vertically and parallel to linkage hook tab.

(f)

With linkage hook pin seated firmly in governor arm slot and governor arm in the minimal gap

position (step 2.(b)), shorten linkage hook assembly until face of vertical tab is flush against

tool. Tighten adjusting screw to 12-15 lb-in. (1 N•m).

(g)

Recheck linkage gap and adjust if necessary.

10.

Disconnect pump and mount in holding fixture.

11.

Using air timing gauge, check pump timing. Set to -2.0 to +0.0 degrees.

12.

Total throttle travel from low-idle to WOT should be 80-84 degrees.

13.

Refer to para. 2-7, Engine Troubleshooting, to diagnose any malfunctions encountered during

checkout.

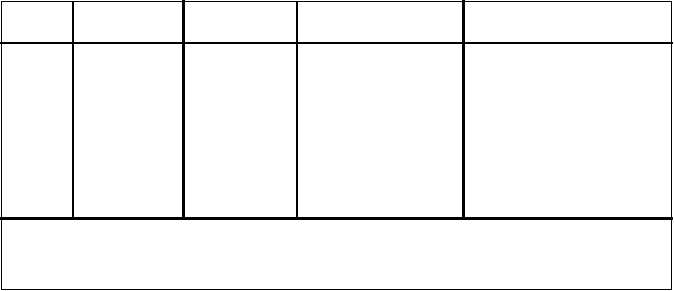

THROTTLE

MM3/

CAM MOVEMENT

RPM

POSITION

STROKE*

(DEGREES)

HOUSING PRESSURE

150

Low idle

25 min.

0-12 psi (0-83 kPa)

400

WOT

35.5 min.

400

WOT**

4 max.

700

Low idle

12-16***

0.5 min.

8-12 psi (55-83 kPa)

700

Low idle

****

0-1 psi (0-7 kPa)**

2000

WOT

51.5 max.

3200

ADJ

21.5-23.5

3.75-16.25

3500

WOT

43.5-48.5

3.25-5.25

3600

WOT

43.5 min.

3800

WOT

30 min.

4050

WOT

15 max.

* Maximum cylinder variation should be ± 6 mm3 from the average flow of all cylinders.

** With electric shut-off solenoid de-energized.

*** Reset using low-idle screw.

**** Minimum of 1.25 degrees more than reading.

|

|