TM 9-2815-237-34

2-140.10

2-35.2. (6.5L) FUEL INJECTION PUMPS (DB2831-5485 OR DB2831-5079) CALIBRATION (Cont’d)

22.

Fuel delivery measurement:

(a)

In order to minimize variations between readings due to residual oil in the graduates, the

following timed cycle should be used:

(1)

Draw

(2)

Settle 30 seconds

(3)

Drain 30 seconds

(4)

Draw

(5)

Settle 30 seconds

(6)

Read graduates

(7)

Repeat cycle and average readings

(b)

Check points:

(1)

At 1500 rpm (WOT), de-energize electric shutoff solenoid. Delivery should be 4 mm3/stroke

maximum.

(2)

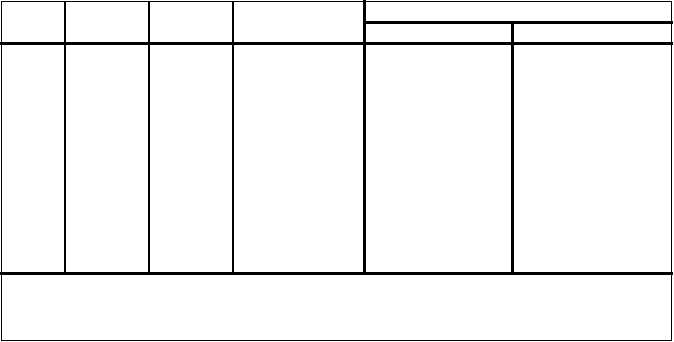

Re-energize electric shutoff solenoid and check delivery against the chart below.

23.

Disconnect pump and mount in holding fixture.

NOTE

Perform step 25 to check pump timing on the DB2831-5079.

24.

Using air timing gauge, check pump timing. Set to +0.25 degree ± 0.50 degree.

25.

Using air timing gauge, check pump timing. Set to 0 ±0.50 degrees

26.

Tighten all fasteners to specifications. Refer to para. 2-32d.

THROTTLE

MM3/

CAM MOVEMENT

PRESSURE

RPM

POSITION

STROKE*

(DEGREES)

TRANSFER PUMP

HOUSING

150

Low-idle

37 min.

16 psi (110 kPa) min.

0-12 psi (0-83 kPa)

400

WOT

58 min.

400

WOT**

4 max.

400

Low-idle***

700

Low-idle

12-16

3.5 min.

8-12 psi (55-83 kPa)

700

Low-idle

1.25 min.

0-1 psi (0-7 kPa)

1500

WOT

4 max.

1500

WOT

68.5-69.5

2000

WOT

56 max.

****

60-62 psi (414-427 kPa)

3200

WOT

59.5 min.

2.50-3.60

3200

ADJ

21.5-23.5

5.25-7.25

3200

Low-idle

11-12

3400

WOT

49-52

3.50-4.50

3500

WOT

45 min.

3650

WOT

31.5 min.

3900

WOT

15 max.

125 psi (862 kPa) max.

* Maximum cylinder variation should be ± 6 mm3 from the average flow of all cylinders.

** With electric shut-off solenoid de-energized.

*** Check electric shutoff solenoid for pull-in with 8.8 volts maximum.

**** Minimum of 1.25 degrees more than reading.

|

|