F-1 GENERAL

TM 9-2815-237-34

APPENDIX F

TORQUE LIMITS

This section provides general torque limits for screws used on the M998 series vehicles. Special torque limits

are indicated in the maintenance procedures for applicable components. The general torque limits given in

this appendix shall be used when specific torque limits are not indicated in the maintenance procedure.

Unless otherwise specified, standard torque tolerance shall be ± 10 percent. These general torque limits

cannot be applied to screws that retain rubber components. The rubber components will be damaged before

the correct torque limit is reached. If a special torque limit is not given in the maintenance instructions,

tighten the screw or nut until it touches the metal bracket, then tighten it one more turn.

F-2. TORQUE LIMITS

Table F-1 lists dry torque limits. Dry torque limits are used on screws that do not have lubricants applied to

the threads. Table F-2 lists wet torque limits. Wet torque limits are used on screws that have high pressure

lubricants applied to the threads.

F-3. HOW TO USE TORQUE TABLE

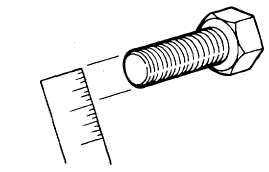

a. Measure the diameter of the screw

you are installing.

c. Under the heading SIZE, look down the left-hand

column until you find the diameter of the screw you

are installing (there will usually be two lines

beginning with the same size).

d. In the second column under SIZE, find the number

of threads per inch that matches the number of

threads you counted in step b.

CAPSCREW HEAD MARKINGS

Manufacturer’s marks may vary.

These are all SAE Grade 5

(3-line).

e. lb find the grade of screw you are installing, match

he markings on the head to the correct picture of

CAPSCREW HEAD MARKINGS on the torque

table.

f. Look down the column under the picture you found

in step e. until you find the torque limit (in lb-ft or

N•m) for the diameter and threads per inch of the

screw you are installing.

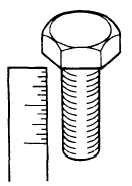

b. Count the number of threads

per inch.

F-1

|

|