TM 9--2815--247--34

0019 00--7

ENGINE RUN--IN -- CONTINUED

0019 00

Final Test -- Continued

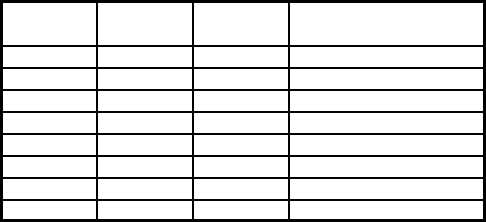

Perform test in accordance with the following test schedule.

Run

No.

Time

(min.)

RPM

Net Observed Torque

(lb--ft)

(NSm)

1

10

825--875

Warm Up

2

15

1000

110

149

3

15

1400

594

805

4

20

1800

1166

1581

5

20

2200

1429

1937

6

20

2400

1518

2058

7

30

2400

1681

2279

8

30

2400

*FR--FL

*FR--FL = Full Rack, Full Load

Set manifold pressure manometers to the local uncorrected wet barometer reading and entrance air inclinometer to

local uncorrected wet barometer reading, as applicable.

Check cylinders for firing by observing exhaust gas temperature. Enter time and RPM at start of each period.

Complete readings as soon as engine temperatures have stabilized. Plot oil consumption every ten minutes at

2400 rpm, full load, during run No. 8. Determine that the governor is not limiting the fuel flow.

The engine shall not exceed the following maximum allowable temperatures when operating at full power setting,

with an air inlet maximum temperature of 120°F (48.9°C), from maximum torque rpm to rated rpm. Air inlet temper-

ature shall be measured at the turbocharger compressor inlet.

Exhaust gas temperature: 1400°F (760°C) measured at individual cylinder ports with turbocharger inlet

air flow restriction less than 1.0 inch of mercury (hg).

Exhaust temperature variation between cylinders shall not exceed 250°F (121.1°C) under full load

conditions, 350°F (176.7°C) below 2100 rpm.

At completion of test schedule, check acceleration, idle speed, and idle oil pressure. Acceleration should be

checked with a moderate steady throttle movement.

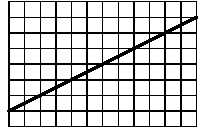

If power is outside limits, check for cause and make correction. Gross corrected horsepower shall be maintained

between 1050 and 1080 at 2400 rpm, full rack and full load in accordance with the following graph.

1800

2000

2200

2400

1050

1015

950

850

ENGINE SPEED -- RPM

HORSEPOWER

LOW IDLE

HIGH IDLE

700 -- 750

2600 -- 2660

|

|