TM 9-2815-250-24&P

3-7.

CRANKSHAFT AND BEARINGS REPAIR (continued).

b.

INSPECTION

Inspect crankshaft for scoring, nicks, and excessive wear. Replace if necessary.

c.

INSTALLATION

1.

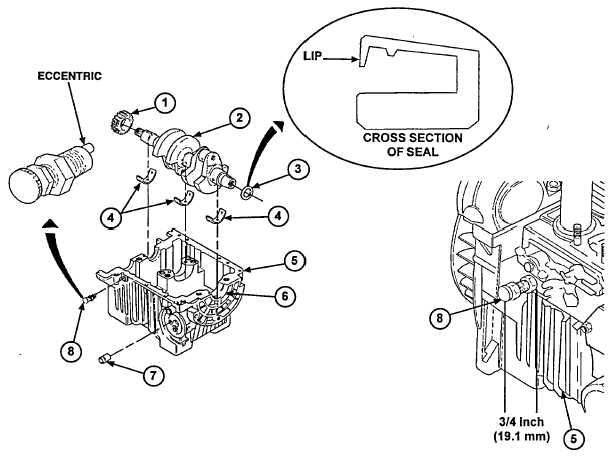

Install relief valve (7) in lower crankcase (5) with grooved side facing auxiliary drive side of engine.

2.

Install crank gear (1) on crankshaft (2). Make sure timing mark is facing end of crankshaft (2).

3.

Apply sealing compound to new seal (3). Install seal (3) on crankshaft (2) with lip facing inward.

4.

Install flow control valve (8) in lower crankcase (5) with eccentric at approximately the 11 o'clock position. Tighten

flow control valve (8) into lower crankcase (5) until it projects 3/4 inch (1 9.1 mm) from lower crankcase (5).

5.

Install three new sleeve bearing halves (4) in three upper crank supports (9), and install three sleeve bearing

halves (4) in three lower crank supports (6). Keep matching bearings together.

6.

Apply light coat of lubricating oil to crankshaft (2). Install crankshaft (2) in lower crankcase (5).

FOLLOW-ON TASKS:

Install camshaft (para 3-11).

Assemble crankcase (para 3-6).

Adjust engine speed (para 3-18).

3-27

|

|