|

|

|

|

|

ARMY TM 9-2815-253-24

AIR FORCE TO 38G1-93-2

MARINE CORPS TM 2815-24/3

d.

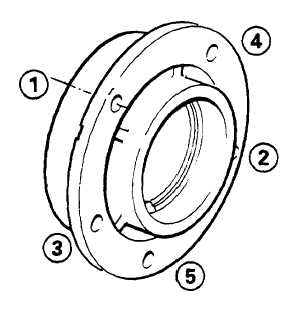

Position housing (3) with shim (4) on crankcase and secure with five capscrews (2). Tighten capscrews to 240 in-

lbs (27.2 Nm) in sequence shown in FIGURE 3-42.

FIGURE 3-42. Bearing Housing Capscrew Tightening Sequence

CAUTION

Striking crankshaft may displace thrust bearings (5) and damage bearing locating tube If It has not

been removed.

e.

Check crankshaft end play. Refer to paragraph 3-33.2.

f.

Install oil seal (6) as follows:

(1)

Place new oil seal (6) squarely into housing (3). Do not use any compound on seal.

(2)

Using a suitable driver against outside face of seal (6), drive seal into bearing housing (3).

g.

Install center bearing locating tube (1) with tapped end facing outward.

h.

Install crankcase door. Refer to paragraph 3-20.2.4.

i.

Install flywheel housing. Refer to paragraph 3-31.2.

3-33. CRANKSHAFT.

3-33.1. Removal.

a.

Drain lubrication system. Refer to end item maintenance manual.

b.

Remove cylinder head assembly. Refer to paragraph 3-27.1.

c.

Remove gear end cover. Refer to paragraph 3-28.1.

d.

Remove flywheel housing. Refer to paragraph 3-31.1.

e.

Remove camshaft. Refer to paragraph 3-29.1.

f.

Remove crankcase door. Refer to paragraph 3-20.2.1.

3-69

|

|

|

|

|

Privacy Statement -

Copyright Information. -

Contact Us