ARMY TM 42815-254-24

AIR FORCE TO 38G1-94-2

N O T E

If bearing gage (PLASTIGAGEPR1) method of checking clearance is

used, omit steps e, f, and g.

e.

Check crankshaft journal and crankpin diameter as follows:

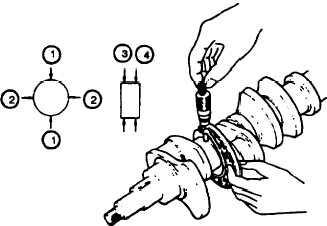

(1) Using a micrometer, measure crankshaft journal diameter at two places, 180 degrees apart and at two

points along its length, refer to FIGURE 3-87.

(2) Repeat step (1) for crankpin.

(3) Standard diameter for crankshaft journal is 2.7548 to 2.7533 in. (69.920 to 69.632 mm), with a limit of

2.7560 in. (69.95 mm). Standard diameter for crankpin is 2.0849 to 2.0854 in. (52.918 to 52.930 mm),

with a limit of 2.0862 in. (52.95 mm). Uneven wear standard value is 0.00004 in. (0.001 mm), with a limit

of 0.002 in. (0.05 mm).

(4) If measured values are less than limits, crankshaft must be replaced or reground.

FIGURE 3-87. Crankshaft Journal and Crankpin Diameter

f.

Check crankshaft journal and bearing clearance as follows:

(1) Install main bearings and bearing caps. Tighten bearing cap bolts to 123 ft-lbs (166.8 Nm).

3-137

|

|