ARMY TM 9-2815-254-24

AIR FORCE TO 38G1-94-2

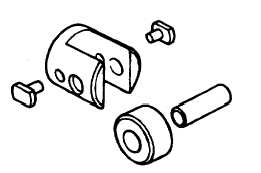

FIGURE 3-26. Feed Pump Tappet

3-11.3.3.

Tuner Assembly.

a.

Visually inspect for broken springs. If springs are broken, replace timer assembly.

b.

Inspect gear (34, FIGURE 3-7) for tooth wear. If defective, replace gear.

c.

Using feeler gage, check clearance between washer (39) and shim (38). Clearance should be 0.0008 to 0.004

in. (0.02 to 0.1 mm). If clearance is not within tolerance, change shim thickness.

3-11.4. Assembly.

3-11.4.1.

a.

b.

c.

d.

e.

f.

Mount base of inserter tool (157924-1620) in a vise.

Install holder (7, FIGURE 3-7) on base.

Install washer (39). shim (38), washer (37), new lockplate (36), and nut (35) on holder (7). Tighten nut 72 to

130 ft-lbs (98 to 176 Nm).

Using a feeler gage, ensure that clearance between washer (39) and shim (38) is 0.0008 to 0.004 in. (0.02

to 0.1 mm). If not change shim thickness.

Bend tab of lockplate (36) to lock nut (35).

Install gear (34) and screws (33). Torque screws 5.8 to 8.7 ft-lbs (7.8 to 11.7 Nm).

3-48

|

|