ARMY TM 9-2815-255-24

AIR FORCE TO 38G1-95-2

MARINE CORPS TM 2815-24/4

(2)

Inspect oil passages to make sure they are open. Use compressed air and a small piece of wire.

(3)

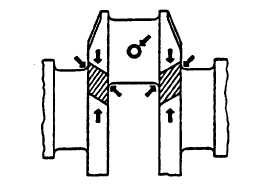

Inspect crankshaft for any signs of load stress, cracks, scoring, or scratches on journals. (An inspection

must be made if the crankshaft damper was found to be damaged or defective.) FIGURE 3-119 shows

critical areas of load stress in a crankshaft.

NOTE

When inspecting crankshaft for cracks, a method (such as the Fluorescent Magnetic Particle

Method) must be used that is capable of detecting minute cracks that are not visible to the eye.

This method magnetizes the crank, employing magnetic particles which are fluorescent and glow

under black light. Replace crankshaft if cracks are found. The crankshaft must be demagnetized

after the test.

(4)

Check each journal for evidence of excessive overheating or discoloration. If either condition exists,

replace crankshaft since heat treatment has probably been destroyed.

FIGURE 3-119. Critical Areas of Crankshaft Load Stress

d.

Measure assembled ID of bearings and OD of crankshaft journals as follows:

(1)

With crankshaft out of engine block, install main bearing inserts and caps (be sure inserts are installed

correctly).

(2)

Tighten main bearing capscrews to 85 ft-lbs (115 Nm).

(3)

Measure ID of all bearings with an inside micrometer. ID of assembled insert should be 3.125 to 3.127

inches (79.39 to 79.44 mm).

(4)

Measure OD of all respective crankshaft journals at several points around journal. OD of main bearing

journal should be 3.123 to 3.124 inches (79.34 to 79.36 mm)

NOTE

If engine has previously had a major overhaul and undersized bearing inserts were used, above

listed ID and OD dimensions may not be the same as those recorded. However, oil clearance

should be within specifications. Oil clearance is 0.0012 to 0.004 inch (0.030 to 0.10 mm). The

maximum serviceable clearance is 0.006 inch (0.15 mm).

(5)

Use crankshaft journal OD measurements to determine if journal is out-of-round or tapered. Journal out-

of-roundness wear limit is 0.003 inch (0.08 mm). Journal taper-per-inch of journal length wear limit is

0.0001 inch (0.025 mm)

(6)

If journals are tapered, out-of-round, scored, or damaged, crankshaft should be ground. Refer to

paragraph 3-44.3. Proper undersize bearings should be installed after grinding.

3-177

|

|