ARMY TM 9-2815-255-24

AIR FORCE TO 38G1-95-2

MARINE CORPS TM 2815-24/4

3-6. MEASURE ENGINE BLOW-BY.

a.

Place a hose with a standard gas gage in end of crankcase vent tube.

b.

Run engine at rated speed and load (engine at operating temperature and run-in, with at least 100 operating

hours).

c.

Measure blow-by over a period of 5 minutes. Multiply figure obtained by 12 (hourly rate). Maximum allowable

blow-by is 225 cu ft/h (6.0 cu m/h)

d.

If blow-by is lower, there probably is no undue wear between piston rings and liners. If blow-by is higher, there

could be excessive wear between piston rings and liners, resulting in loss of engine power.

3-7. INTAKE MANIFOLD PRESSURE CHECK.

a.

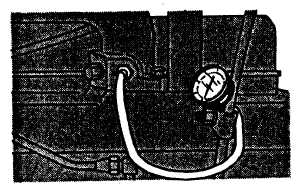

Remove plug from intake manifold and connect suitable gage to intake manifold, refer to FIGURE 3-1.

FIGURE 3-1. Connecting Test Gage to Intake Manifold

b.

Run engine to bring up to normal operating temperature. (From a cold start, operate engine 10 to 15 minutes at

slow idle.)

NOTE

Engine speed and load should be stabilized before taking readings on gage. Be sure that gage

works properly.

3-19

|

|