ARMY TM 9-2815-256-24

AIR FORCE TO 38G1-96-2

MARINE CORPS TM 2815-24/5

k.

Clean cylinder liner bores with waterless hand cleaner after installation.

I.

Wipe dry with clean towels.

m.

Apply a thin coat of clean engine lubricating oil (MIL-L-2104) immediately to ID of liners to prevent

corrosion.

3-49.3.

Pistons and Connecting Rods.

a.

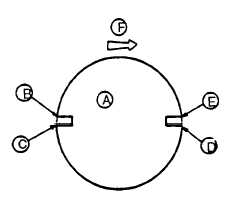

Ensure piston ring gaps are staggered as described in paragraph 3-48.1., and as shown on FIGURE 3-167.

b.

Coat pistons liners and inside of ring compressor with clean engine lubricating oil (MIL-L-2104).

c.

Carefully place ring compressor with piston and rod over liner.

FIGURE 3-167. Staggered Piston Ring Gaps

CAUTION

Be sure crankshaft journals and liner walls are not damaged by rod when installing piston Be sure

crankshaft journals and liner walls are not damaged by rod when installing piston and rod in liner.

CAUTION

Be sure word FRONT on side of rod and side or top of piston faces toward front of engine. If FRONT

is not visible on side or top of pistons, install piston on rod so that offset in combustion bowl is

opposite camshaft side of engine. Long side of connecting rod should face camshaft side of block.

d.

With piston centered in ring compressor and rings staggered correctly, push piston into liner.

e.

Install one bearing insert in connecting rod with tang (A, FIGURE 3-168) in groove (B). Put clean engine

lubricating oil (MIL-L-2104) on insert and crankshaft journal. Carefully pull connecting rod with insert to

crankshaft journal.

3-214

|

|