ARMY TM 9-2815-257-24

AIR FORCE TO 38G1-128-2

MARINE CORPS TM 10155A/2815-24/3

3-20

3-15. ROCKER ARM ASSEMBLY MAINTENANCE

This task covers head cover removal, rocker arm / valve clearance adjustment, and head cover installation.

INITIAL SETUP

Tools:

Equipment Condition:

Tool Kit, General Mechanic’s Automotive

Engine cool

(Item 2, App. B, Sect. III)

A. HEAD COVER REMOVAL.

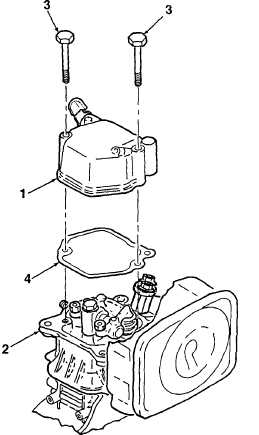

Remove head cover (1, Figure 3-5) from cylinder

head (2) by removing bolts (3). Remove cover

gasket (4) only if replacement is required.

B. VALVE CLEARANCE ADJUSTMENT.

1.

Remove flywheel housing and recoil starter as an

assembly (Para. 3-13).

2.

Rotate flywheel in the clockwise direction until T

mark on flywheel match V mark on cylinder body

fin. This is the top dead center (TDC) position.

Intake and exhaust valves will be in closed

position.

3.

Using a feeler gauge, check rocker arm to valve

clearance (Figure 3-6). Clearance shall be 0.0039

to 0.0059 inch (0.10 to 0.15 mm). Drag on feeler

gauge when passing through gap shall be

minimal.

4.

If adjustment is required, loosen lock nut and

rotate adjusting screw clockwise / counter-

clockwise to expand / reduce gap. Tighten lock

nut and recheck clearance.

5.

Repeat steps 3 and 4 until proper clearance is

attained.

Figure 3-5. Head Cover Removal

|

|