ARMY TM 9-2815-257-24

AIR FORCE TO 38G1-128-2

MARINE CORPS TM 10155A/2815-24/3

4-18

4-12. FUEL INJECTION PUMP MAINTENANCE - cont.

B. CLEANING.

Cleaning solvents are flammable and toxic to

eye, skin, and respiratory tract. Skin and eye

protections are required when working in

contact with cleaning solvents. Avoid

repeated or prolonged contact. Work in well

ventilated area only. Keep away from heat,

sparks, and open flame. Do not smoke while

using cleaning solvent. Failure to observe this

warning can result in injury or death to

personnel.

Clean components with cleaning solvent and a

clean rag. Allow to air dry.

C. INSPECTION.

1.

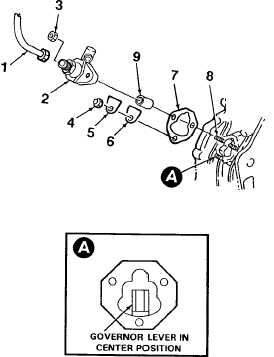

Inspect fuel pipe (1, Figure 4-12) for cracks,

kinks, and leaks. Inspect injection pump (2) for

crossed, stripped, or damaged threads. Replace if

damaged.

2.

Inspect fuel tappet (9) for scores, pitting, or wear.

Replace if damaged or worn.

D. INSTALLATION.

1.

Install fuel tappet (9, Figure 4-12) into engine

crankcase.

2.

Install shim(s) (7) onto injection pump studs (8).

Install gasket (6), cover (5), and nut (4).

3.

Install injection pump (2) onto studs (8), aligning

tooth on control lever with slot on governor lever

(see Figure 4-12). Governor lever must be set so

slot is in the center of opening in housing. Install

nuts (3) and tighten to 7.2 to 8.7 ft-lbs. (100 to

120 kg-cm).

Figure 4-12. Fuel Injection Pump Installation

WARNING

|

|