ARMY TM 9-2815-259-24

AIR FORCE TO 38G1-125-2

MARINE CORPS 09249A/09246A-24

5-104

__________

WARNING

Compressed air used for cleaning can create airborne particles that may

enter the eyes. Never exceed 30 psi (207 kPa) of pressure. Eye protection

required. Failure to comply could result in serious eye damage or

blindness.

(3)

Clean oil pump parts in cleaning solvent. Dry with compressed air.

(4)

Inspect oil pump components for excessive wear. Replace parts or oil pump assembly as

necessary.

(5)

Inspect outlet tube (8) and pick-up tube assembly (4) for cracks or defects. Replace parts as

necessary.

(6)

Install idler gear (12) and drive gear (13).

(7)

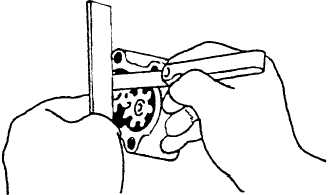

Using straight edge and feeler gage, check axial clearance between idler gear (12) and housing (11,

Figure 5-86), refer to Figure 5-87. Replace oil pump if clearance is not 0.0018 - 0.0065 in. (0.045

- 0.165 mm).

FIGURE 5-87. OIL PUMP AXIAL CLEARANCE

(8)

Using straight edge and feeler gage, check axial clearance between drive gear (13) and housing

(11), refer to Figure 5-87. Replace oil pump if clearance is not 0.0018 - 0.0065 in. (0.045 - 0.165

mm).

(9)

Using feeler gage, check radial clearance between idler gear (12) and housing (11), refer to Figure

5-86. Replace oil pump if clearance is not 0.005 - 0.008 in. (0.131 - 0.211 mm).

(10)

Using feeler gage, check radial clearance between drive gear (13) and housing (11), refer to Figure

5-88. Replace oil pump if clearance is not 0.005 - 0.008 in. (0.131 - 0.211 mm).

(11)

Remove idler gear (12, Figure 5-86).

|

|