ARMY TM 9-2815-259-24

AIR FORCE TO 38G1-125-2

MARINE CORPS 09249A/09246A-24

5-110

2

Exhaust valve outer diameter should be 0.3090 - 0.3100 in. (7.848 - 7.874 mm).

(e)

Use valve inspection center (D-05058ST) to determine if valves are out of round, bent or

warped. Maximum valve face runout is 0.0015 in. (0.038 mm). Replace valves not

within specifications.

CAUTION

Do not nick valve head-to-stem radius while grinding valves. A nick could

cause valve to break. Break all sharp edges after grinding valve. Failure to

comply could result in damage to engine.

(f)

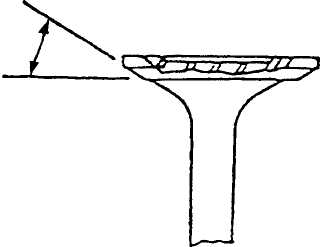

Reface valve to 29.25° ± 0.25° using valve refacing station, refer to Figure 5-90.

(4)

Clean, inspect, and measure cylinder head as follows:

(a)

Inspect combustion face for evidence of physical damage, oil or coolant leakage, or

gasket failure. Repair or replace cylinder head if there is evidence of physical damage;

such as cracking, abrasion, distortion, or valve seat “torching”. Inspect all cylinder head

passages for restrictions.

FIGURE 5-90. VALVE FACE ANGLE

(b)

Remove all plugs from cylinder head.

(c)

Scrape gasket material, oil, carbon, and rust from cylinder head. Use a powered wire

brush to clean sealing surfaces.

|

|